EN

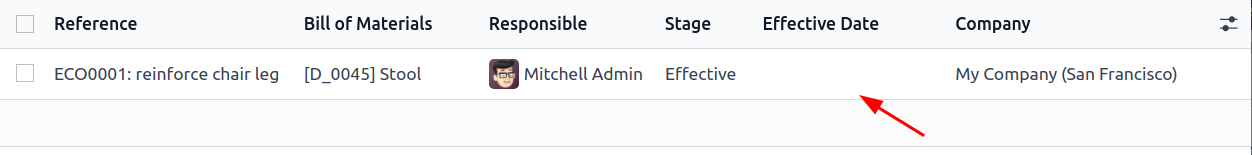

Odoo 18

Manufacturing

Odoo Manufacturing helps manufacturers schedule, plan, and process manufacturing orders. With the work center control panel, put tablets on the shop floor to control work orders in real-time and allow workers to trigger maintenance operations, feedback loops, quality issues, etc.

See also

- Odoo Tutorials: MRP

- Odoo Tutorials: Barcode Scanner

- IoT Boxes (MES)

- Basic setup

- Advanced configuration

- Workflows

- Shop Floor

- Subcontracting

- Reporting

Get Help

Contact Support Ask the Odoo Community

- User Docs

- Database management

- Developer

- Contributing

EN

Odoo 18

Manufacturing product configuration

In order to manufacture a product in Odoo Manufacturing, the product must be properly configured. Doing so consists of enabling the Manufacturing route and configuring a bill of materials (BoM) for the product. Once these steps are completed, the product is selectable when creating a new manufacturing order.

Activate the Manufacture route

The Manufacture route is activated for each product on its own product page. To do so, begin by navigating to Manufacturing ‣ Products ‣ Products. Then, select an existing product, or create a new one by clicking New.

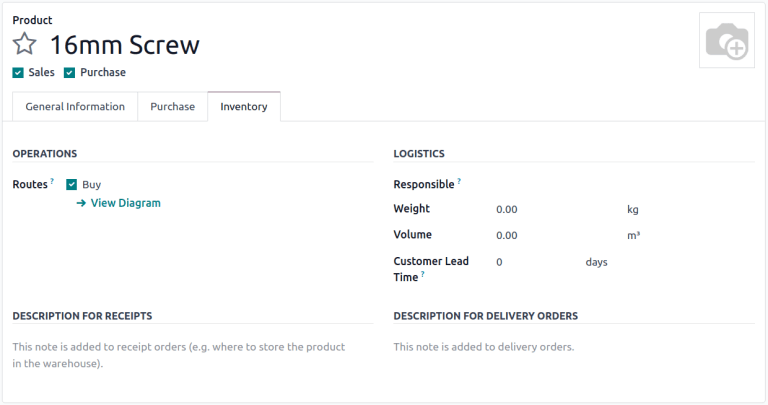

On the product page, select the Inventory tab, then enable the Manufacture checkbox in the Routes section. This tells Odoo the product can be manufactured.

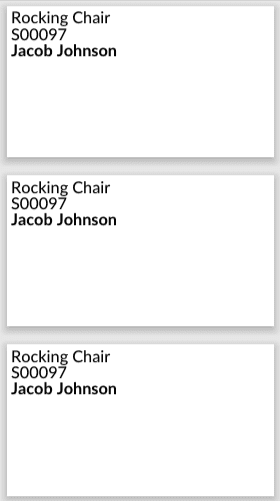

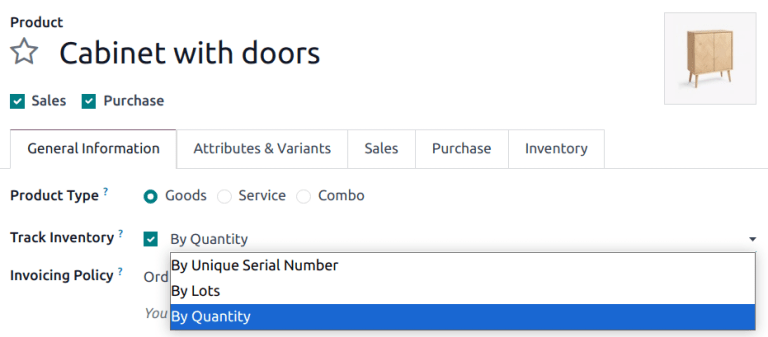

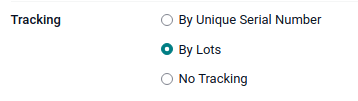

Lot/serial number tracking

The assignment of lots or serial numbers to newly manufactured products is optional. To optionally assign lots or serial numbers to newly manufactured products, go to the Traceability section in the Inventory tab. In the Tracking field, select By Unique Serial Number or By Lots.

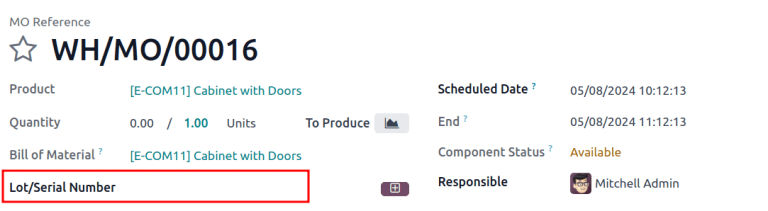

Doing so enables the Lot/Serial Number field on a manufacturing order, or the Register Production instruction on a work order card in the Shop Floor app.

Lot/Serial Number field on the MO.

Register Production option to generate lot/serial number on a work order card.

Configure a bill of materials (BoM)

Next, a BoM must be configured for the product so Odoo knows how it is manufactured. A BoM is a list of the components and operations required to manufacture a product.

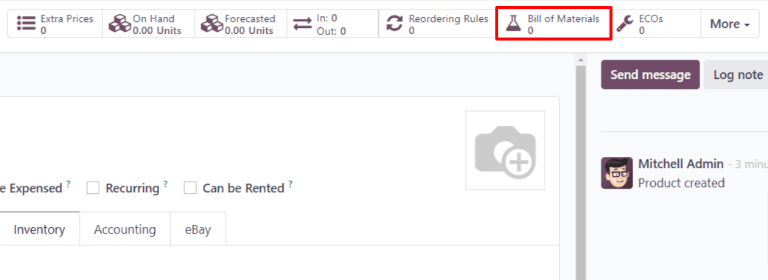

To create a BoM for a specific product, navigate to Manufacturing ‣ Products ‣ Products, then select the product. On the product page, click the Bill of Materials smart button at the top of the page, then select New to configure a new BoM.

On the BoM, the Product field auto-populates with the product. In the Quantity field, specify the number of units that the BoM produces.

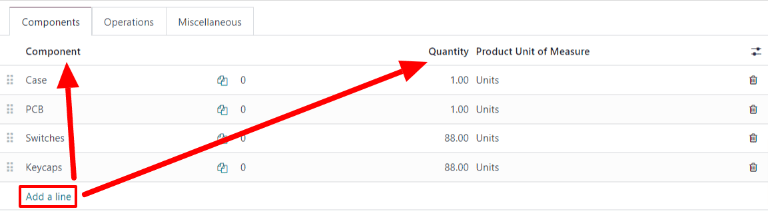

Add a component to the BoM by selecting the Components tab and clicking Add a line. Select a component from the Component drop-down menu, then enter the quantity in the Quantity field. Continue adding components on new lines until all components have been added.

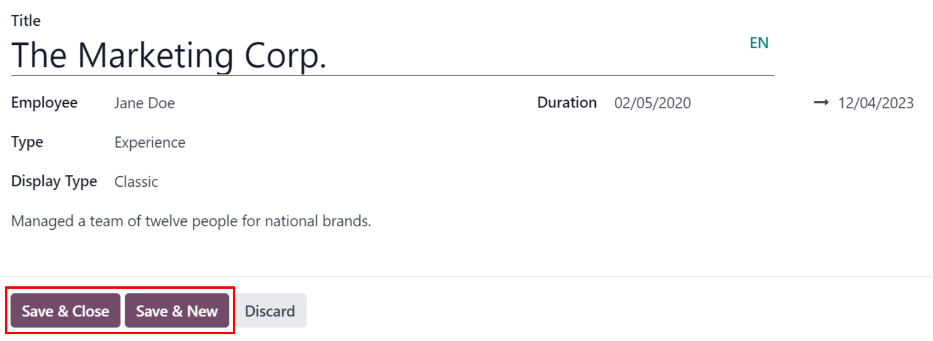

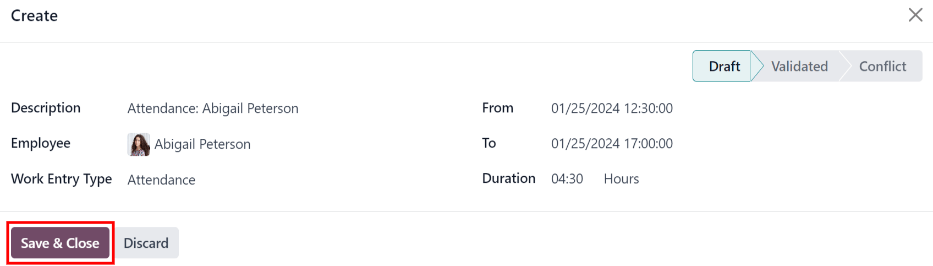

Next, select the Operations tab. Click Add a line and a Create Operations pop-up window appears. In the Operation field, specify the name of the operation being added (e.g. Assemble, Cut, etc.). Select the work center where the operation will be carried out from the Work Center drop-down menu. Finally, click Save & Close to finish adding operations, or Save & New to add more.

Important

The Operations tab only appears if the Work Orders setting is enabled. To do so, navigate to Manufacturing ‣ Configuration ‣ Settings, then enable the Work Orders checkbox.

Learn more

The section above provides instructions for creating a basic BoM that allows a product to be manufactured in Odoo. However, it is by no means an exhaustive summary of all the options available when configuring a BoM. For more information about bills of materials, see the documentation on how to create a bill of materials.

On this page

Get Help

Contact Support Ask the Odoo Community

- User Docs

- Database management

- Developer

- Contributing

EN

Odoo 18

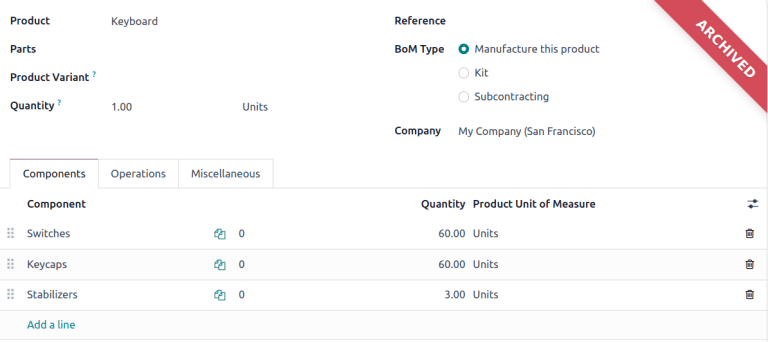

Bill of materials

A bill of materials (or BoM for short) documents specific components, along with their respective quantities, that are needed to produce or repair a product. In Odoo, BoMs as blueprints for manufactured goods and kits, and often include production operations and step-by-step guidelines, as well.

BoM setup

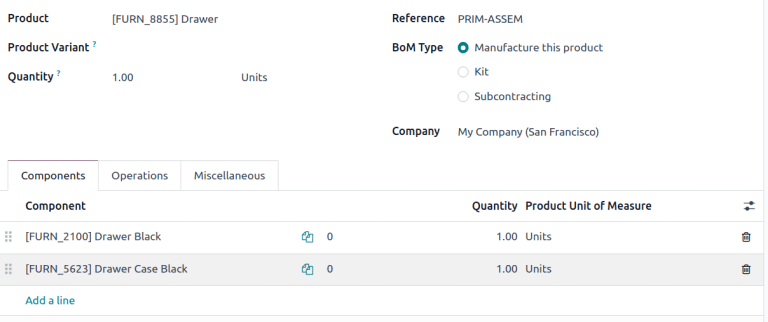

To create a BoM, go to Manufacturing app ‣ Products ‣ Bills of Materials and click New.

Next, set the BoM Type to Manufacture this Product.

Then, specify required components and, if necessary, define any manufacturing operations.

Tip

Individual BoMs can also be quickly accessed or created by clicking the Bill of Materials smart button on any product form, as accessible through the Sales, Inventory, and Manufacturing apps, as well as through any internal links where a product is referenced (such as in a field or a line item).

BoM for Drawer, displaying the Components tab.

See also

Components

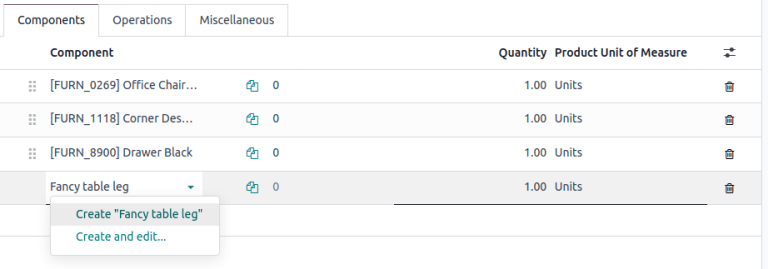

In the Components tab of a BoM, specify components used to manufacture the product by clicking Add a line. From the Components drop-down menu, select from existing products or create a new product by typing the name and selecting either the Create ” “ option to quickly add the line item, or the Create and edit… option to add the component and continue to its configuration form.

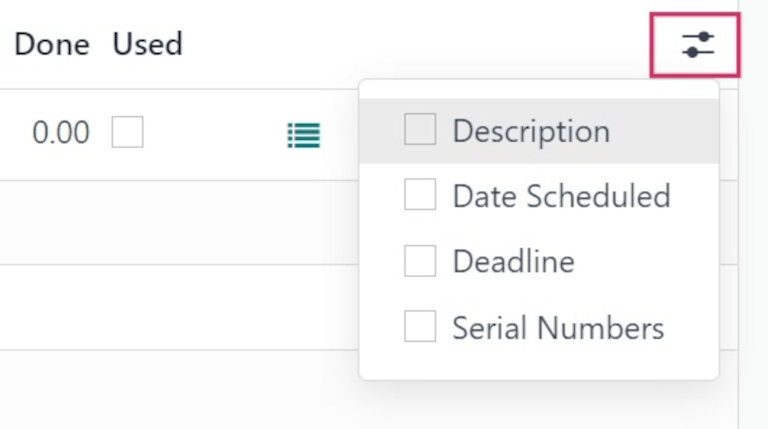

Optionally, access additional fields by clicking the (settings adjust) icon to the far-right of the Components tab. Tick the checkboxes for the following features to enable these columns:

- Apply on Variants: specify which product variant each component is used in. When the field is left blank, the component is used in all product variants.

- Consumed in Operation: specify the operation using the component. Useful for determining manufacturing readiness.

- Manual Consumption: tick the checkbox to force operators to check the Consumed checkbox on a manufacturing order (MO).

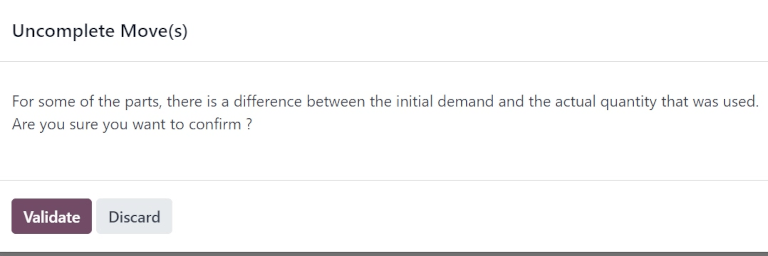

Not doing so triggers the Consumption Warning error message, where the consumed component quantity must be manually inputted. Otherwise, the operation cannot be completed.

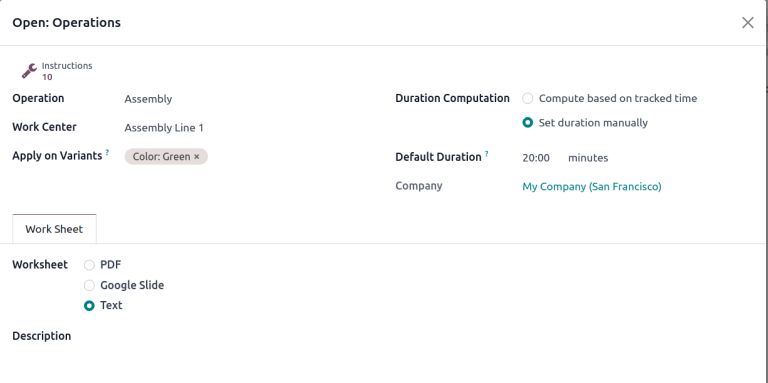

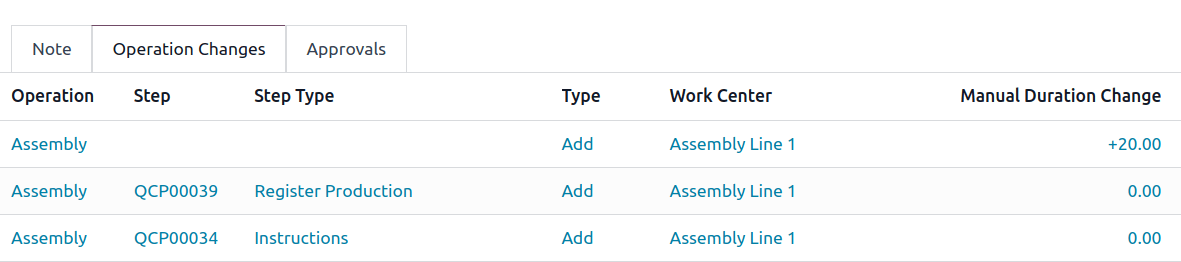

Operations

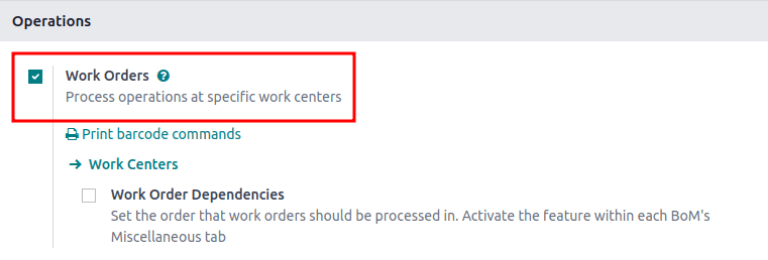

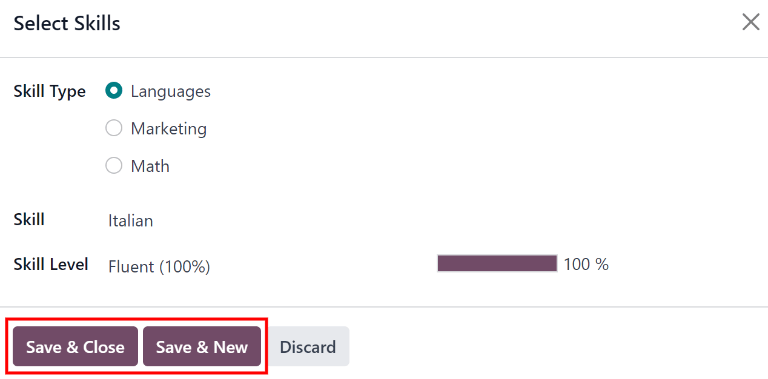

Add an operation to a BoM to specify instructions for production and register time spent on an operation. To use this feature, first enable the Work Orders feature by going to Manufacturing app ‣ Configuration ‣ Settings. In the Operations section, tick the Work Orders checkbox to enable the feature.

See also

Next, navigate to the BoM by going to Manufacturing app ‣ Products ‣ Bill of Materials and selecting the desired BoM. To add a new operation, go to the Operations tab, and click Add a line.

Doing so opens the Create Operations pop-up window, where the various fields of the operation are configured:

- Operation: name of the operation.

- Work Center: select existing locations to perform the operation, or create a new work center by typing the name and selecting the Create ” “ option.

- Apply on Variants: specify if this operation is only available for certain product variants. If the operation applies to all product variants, leave this field blank.

See also

Configuring BoMs for product variants - Duration Computation: choose how time spent on the operation is tracked. Opt for Compute based on tracked time to use the operation’s time tracker or Set duration manually if operators can record and modify time themselves.

Choosing the Compute based on tracked time option enables the Based on last __ work orders option, which automatically estimates the time to complete this operation based on the last few operations. Choosing Set duration manually enables the Default Duration field instead. - Default Duration: estimated amount of time to complete the operation; used for planning manufacturing orders and determining work center availability.

- Company: specify the company the BoM is available in.

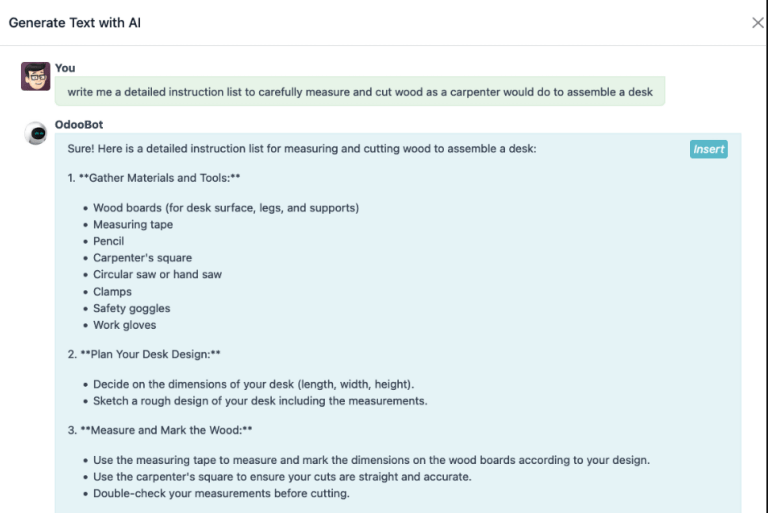

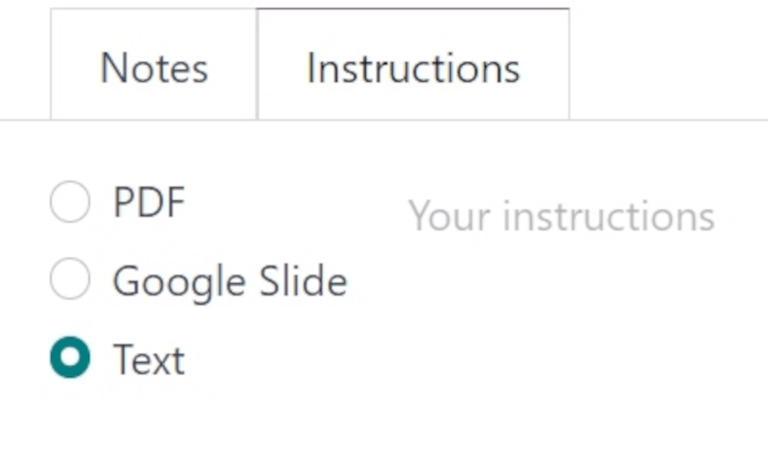

Include operation details in the Work Sheet tab. Choose PDF to attach a file or Google Slide with public access to share a link. Select Text to type instructions in the Description text field.

Tip

Type / for a list of formatting options and features, including ChatGPT.

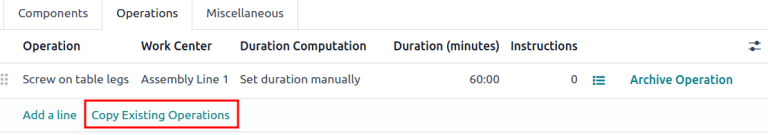

Finally, click Save & Close to close the pop-up window. To add more operations, click Save & New and repeat the same steps above to configure another operation.

Note

Each operation is unique, as it is always exclusively linked to one BoM.

Tip

After creating an operation, click the Copy Existing Operations button to choose an operation to duplicate.

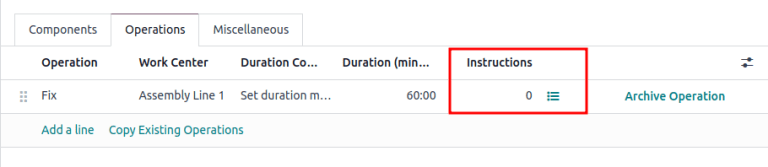

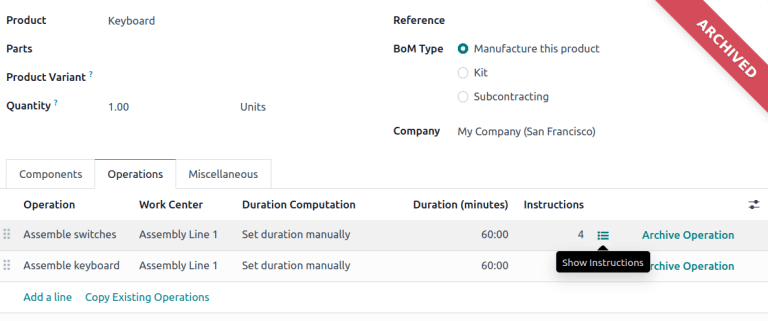

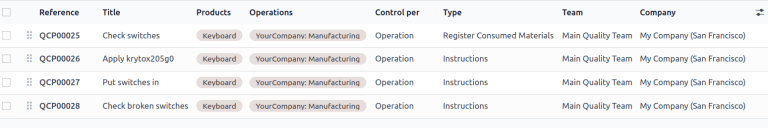

Instructions

Important

To add detailed instructions to operations, the Quality app must be installed.

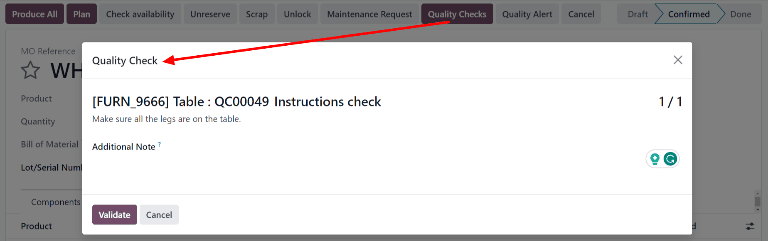

Add specific instructions to an existing operation by clicking the operation’s (list) icon in the Instructions column. The number in the Instructions column shows the number of existing detailed instructions there are for the operation.

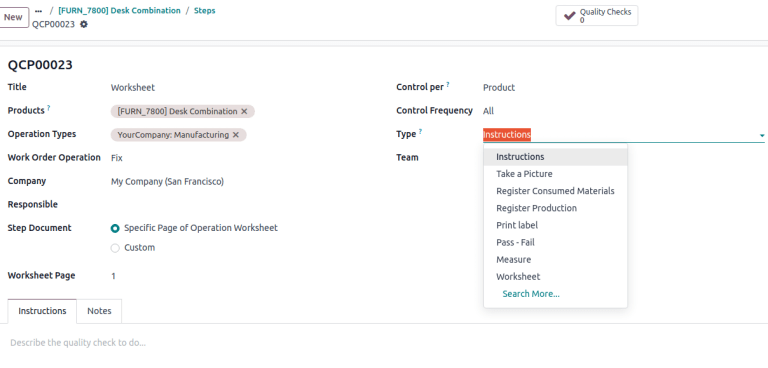

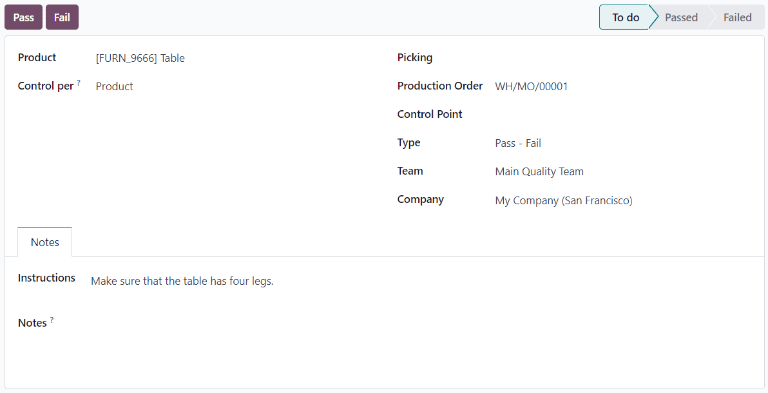

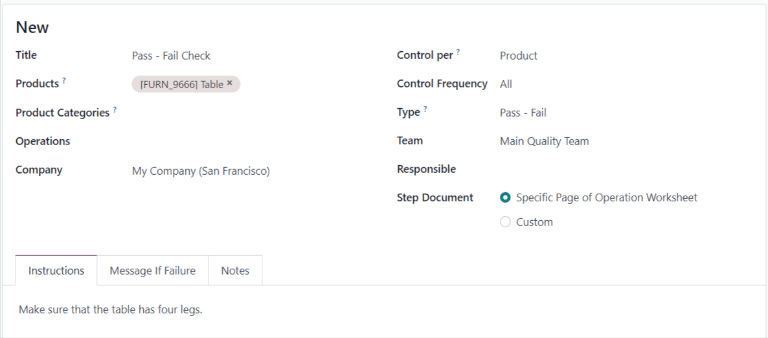

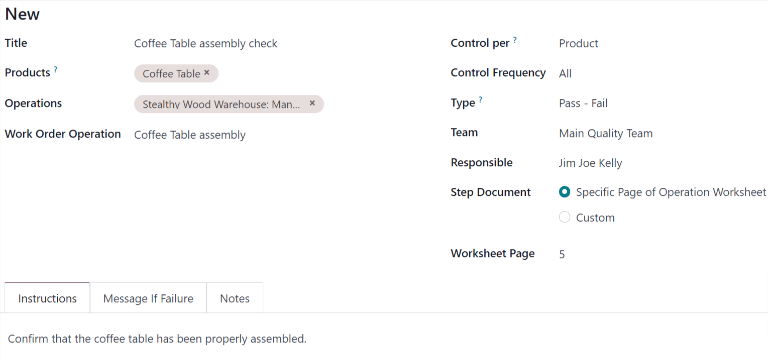

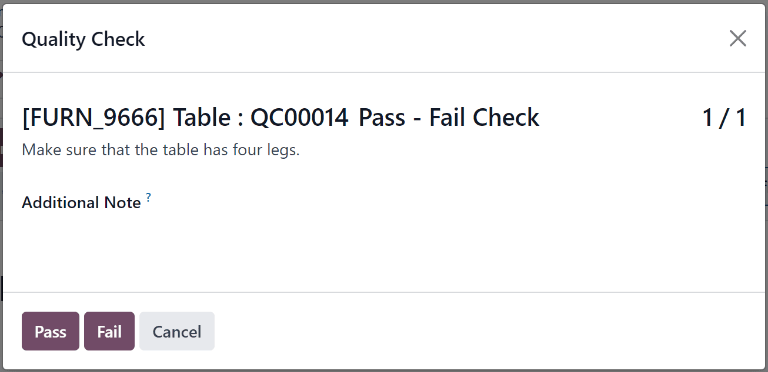

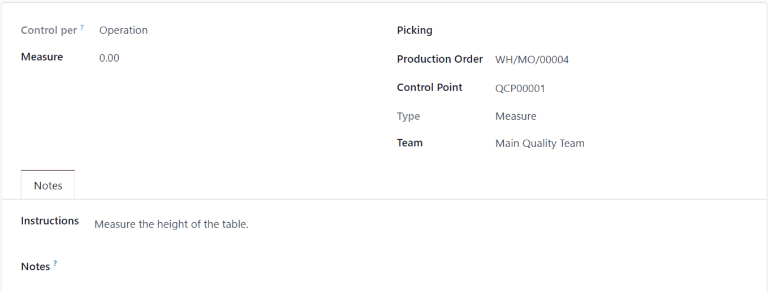

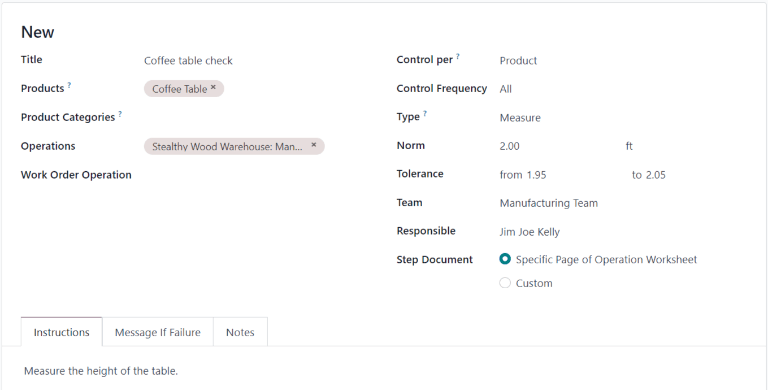

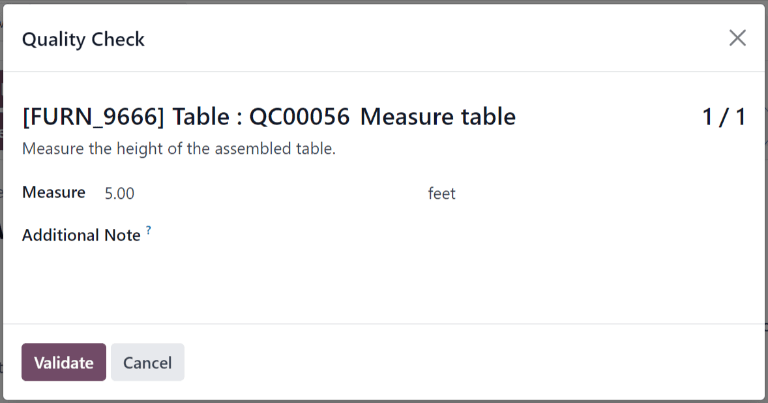

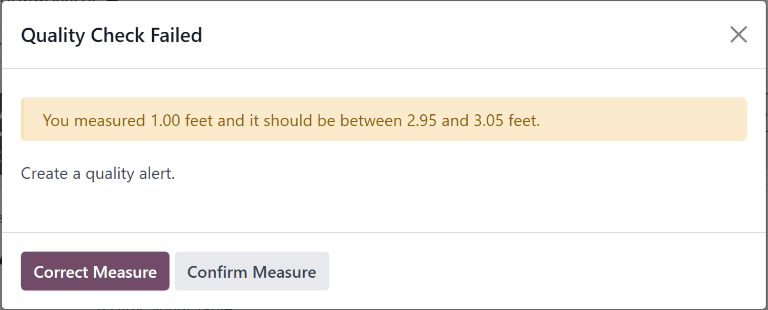

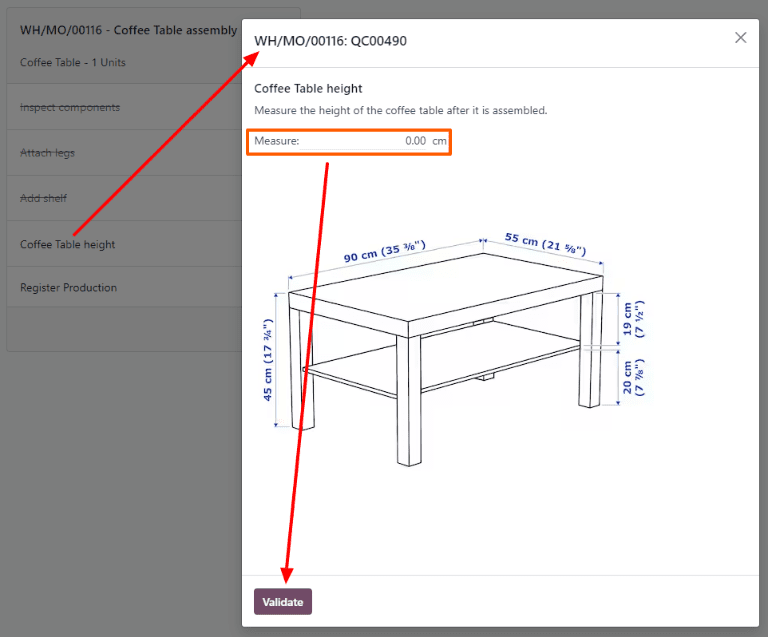

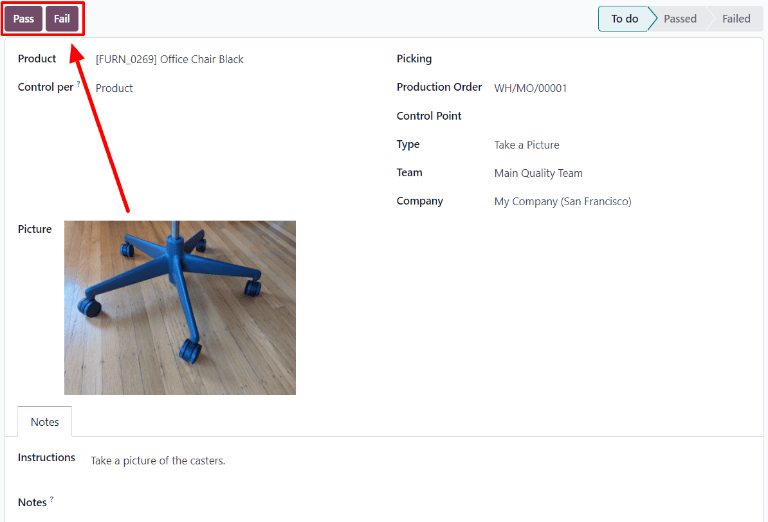

On the Steps dashboard, click New to open a blank quality control point form where the new manufacturing step can be created. Here, give the specific instruction a Title and set the Type to Instructions. In the Instructions tab of the form, write out the directions for the step in the operation.

Note

Further customizations can be made here on this form, beyond ordinary instructions, to also include specific types of quality control points that carry specific (or complex) conditions. For more details about quality control points refer the Instruction check documentation.

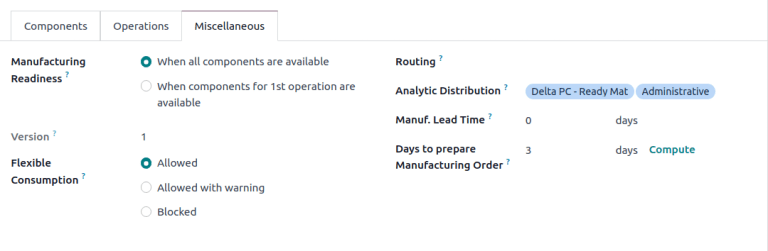

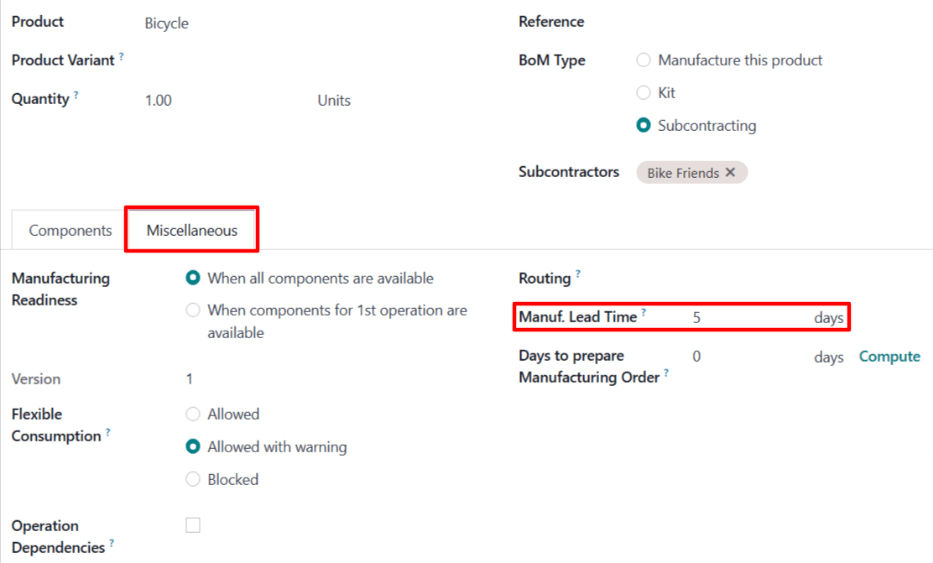

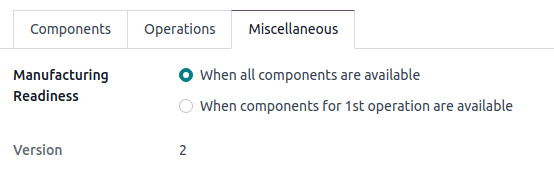

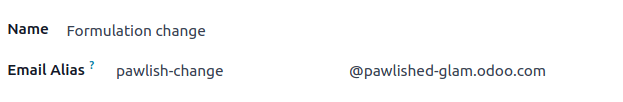

Miscellaneous

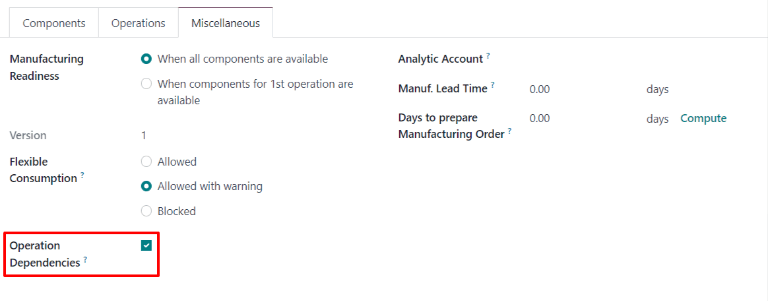

The Miscellaneous tab contains more BoM configurations to customize procurement, calculate costs, and define how components are consumed.

- Manufacturing Readiness: choosing When components for the 1st operation are available shows the Component Status as a green Not Available, when only the components that are consumed in the first operation are in stock. This indicates that although not all components are available, operators can at least begin with the first operation. Choosing When all components are available displays a red Not Available component status unless all components are in available.

Tip

Specify which operation consumes each component on the BoM in the Manual Consumption field.

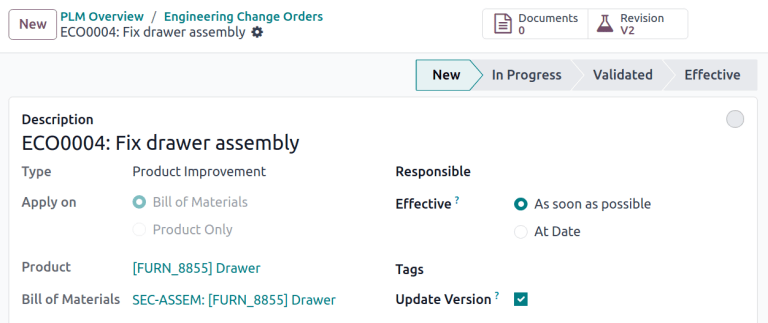

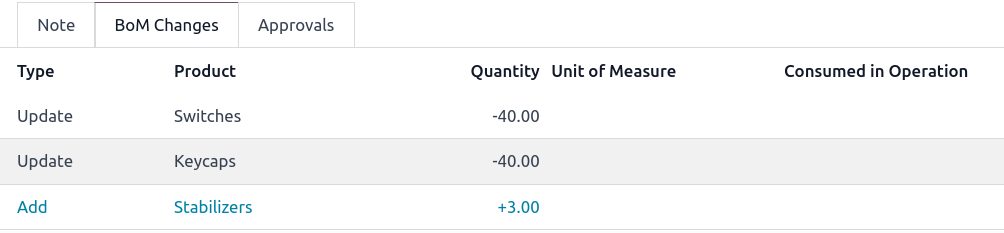

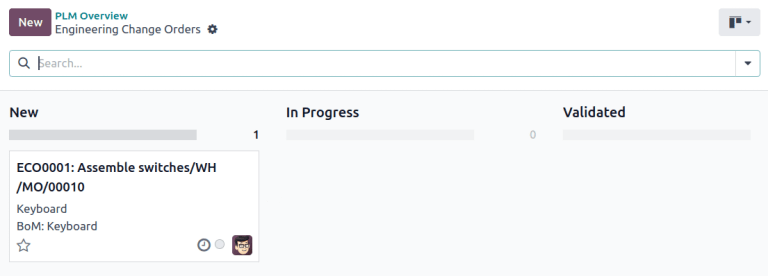

- Version: displays the current BoM version, visible with the Odoo PLM app installed for managing BoM changes.

- Flexible Consumption: specifies if components used can deviate from the quantity defined on the BoM. Choose Blocked if operators must adhere strictly to the BoM quantity. Otherwise, choose Allowed or Allowed with Warning.

- Routing: select the preferred warehouse’s manufacturing operation type for products produced in multiple warehouses. If left blank, this warehouse’s Manufacturing operation type is used by default.

- Analytic Distribution: select pre-created analytic distribution models from the list to automatically record the cost of manufacturing products in the chosen journal.

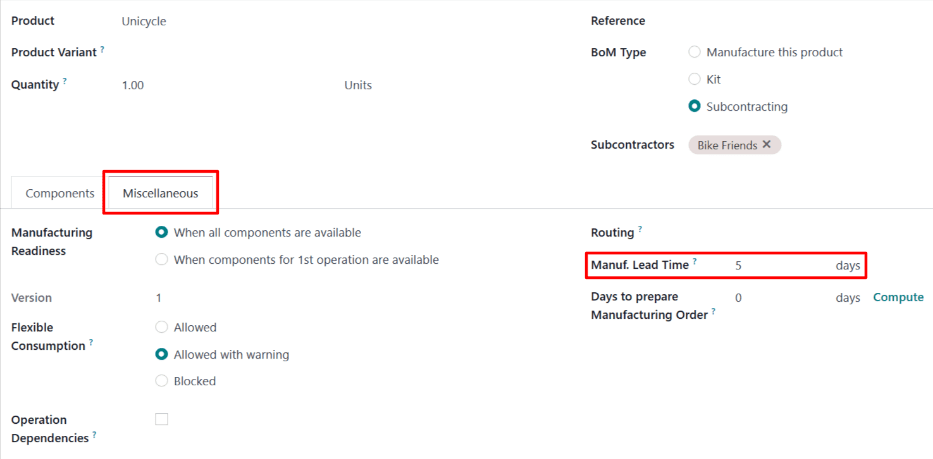

- Manuf Lead Time: define the number of days needed to complete a MO from the date of confirmation.

- Days to prepare Manufacturing Order: number of days needed to replenish components, or manufacture sub-assemblies of the product.

See also

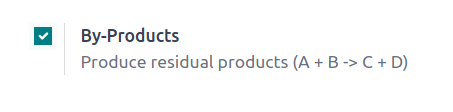

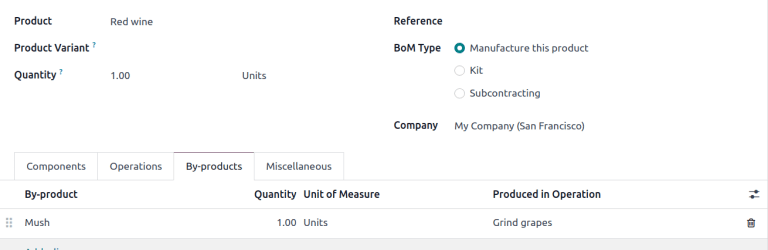

Add by-products to BoMs

A by-product is a residual product that is created during production in addition to the main product of a BoM. Unlike the primary product, there can be more than one by-product on a BoM.

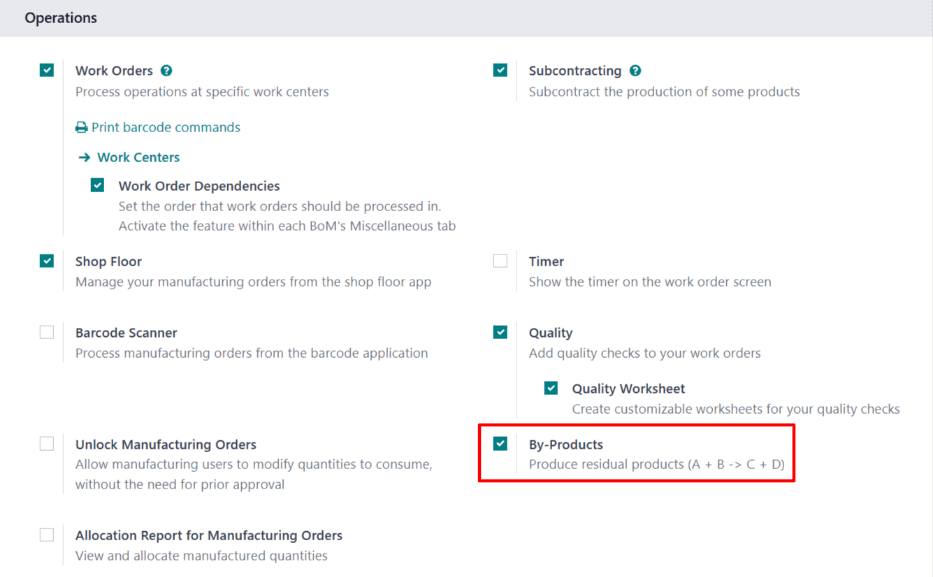

To add by-products to a BoM, first enable the By-Products feature in Manufacturing app ‣ Configuration ‣ Settings. In the Operations section, tick the checkbox for By-Products to enable the feature.

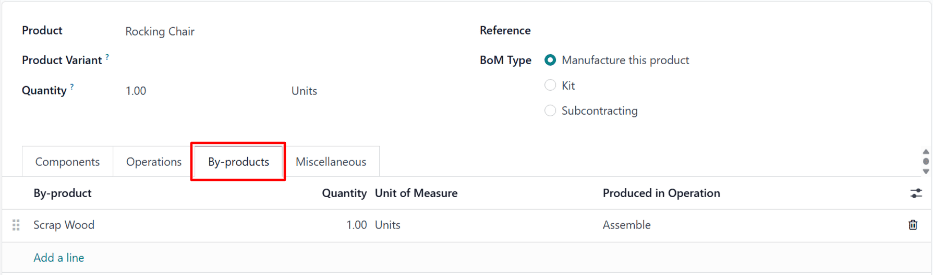

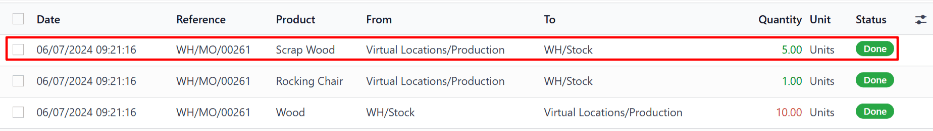

Once the feature is enabled, add by-products to a BoM by clicking the By-products tab. Click Add a line, and fill in the By-product, Quantity, and Unit of Measure. Optionally, specify a Produced in Operation for the by-product.

Example

The by-product, Mush, is created in the Grind grapes operation when producing Red Wine.

On this page

Get Help

Contact Support Ask the Odoo Community

- User Docs

- Database management

- Developer

- Contributing

EN

Odoo 18

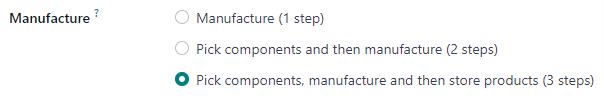

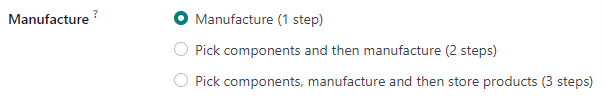

One-step manufacturing

Odoo Manufacturing allows users to manufacture products using one, two, or three steps. When using one-step manufacturing, Odoo creates a manufacturing order (MO), but does not generate transfers for the movement of components out of inventory or finished products into stock. Inventory counts still update based on the number of components used and products manufactured, but the act of transferring them to and from inventory is not tracked.

Tip

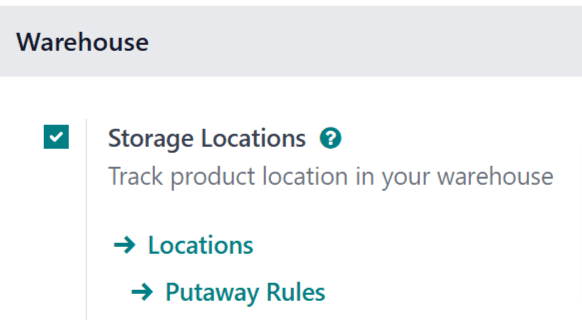

The number of steps used in manufacturing is set at the warehouse level, allowing for each warehouse to use a different number of steps. To change the number of steps used for a specific warehouse, begin by navigating to Inventory ‣ Configuration ‣ Warehouses, and then select a warehouse from the Warehouses screen.

On the Warehouse Configuration tab, find the Manufacture radio input field, and select one of the three options: Manufacture (1 step), Pick components and then manufacture (2 steps), or Pick components, manufacture and then store products (3 steps).

Important

Products must be properly configured before they can be manufactured in Odoo. For details on how to do so, see the documentation on how to configure a product for manufacturing.

Create manufacturing order

To manufacture a product in Odoo Manufacturing, begin by navigating to Manufacturing ‣ Operations ‣ Manufacturing Orders, and then click New to create a new MO.

On the new MO, select the product to be produced from the Product drop-down menu. The Bill of Material field auto-populates with the associated bill of materials (BoM).

If a product has more than one BoM configured for it, the specific BoM can be selected in the Bill of Material field, and the Product field auto-populates with the associated product.

After a BoM has been selected, the Components and Work Orders tabs auto-populate with the components and operations specified on the BoM. If additional components or operations are required for the MO being configured, add them to the Components and Work Orders tabs by clicking Add a line.

Finally, click Confirm to confirm the MO.

Process manufacturing order

An MO is processed by completing all of the work orders listed under its Work Orders tab. This can be done on the MO itself, or from the work order tablet view.

Basic workflow

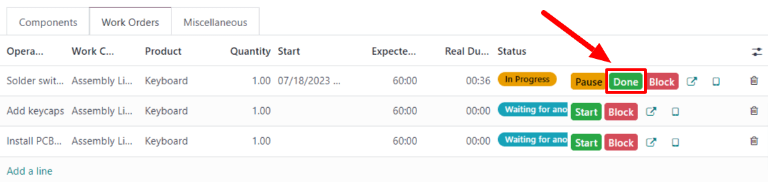

To complete work orders from the MO itself, begin by navigating to Manufacturing ‣ Operations ‣ Manufacturing Orders, and then select an MO.

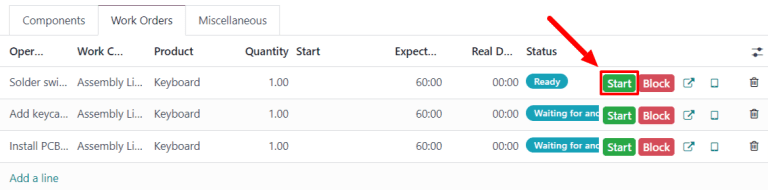

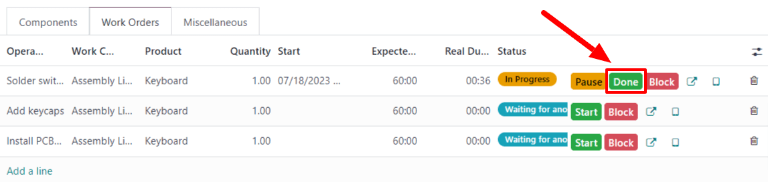

On the MO page, select the Work Orders tab. Once work begins on the first work order that needs to be completed, click the Start button for that work order. Odoo Manufacturing then starts a timer that keeps track of how long the work order takes to complete.

When the work order is completed, click the Done button for that work order. Repeat the same process for each work order listed on the Work Orders tab.

After completing all of the work orders, click Produce All at the top of the screen to mark the MO as Done, and register the manufactured product(s) into inventory.

Shop Floor workflow

To complete the work orders for an MO using the Shop Floor module, begin by navigating to Manufacturing ‣ Operations ‣ Manufacturing Orders, and then select an MO.

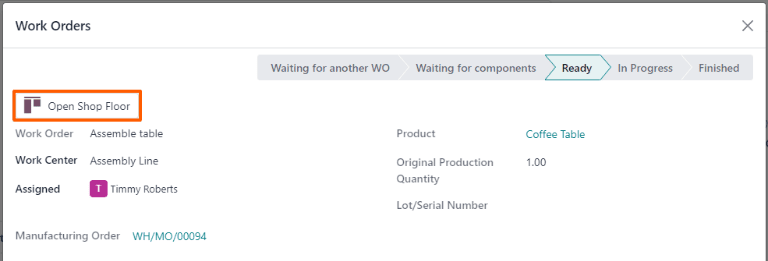

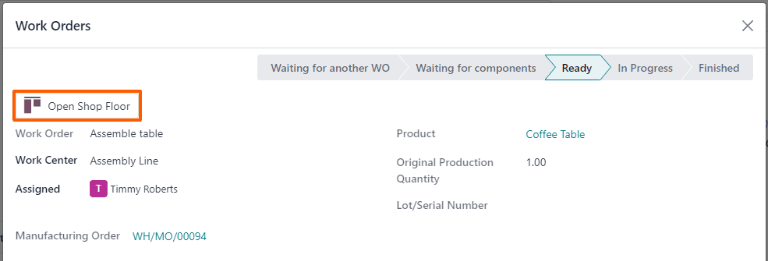

On the MO, click on the Work Orders tab, and then select the ↗️ (square with arrow coming out of it) button on the line of the first work order to be processed. Doing so opens a Work Orders pop-up window, with details and processing options for the work order.

On the pop-up window, select the Open Shop Floor button at the top-left of the window to open the Shop Floor module.

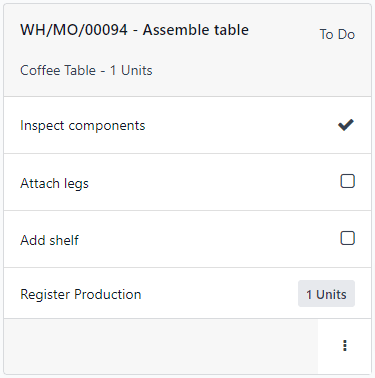

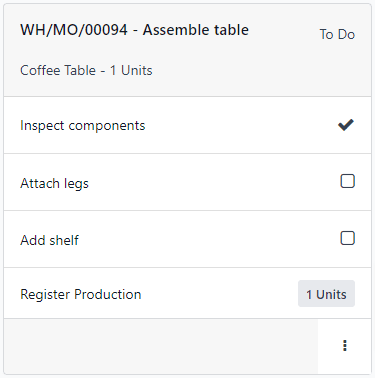

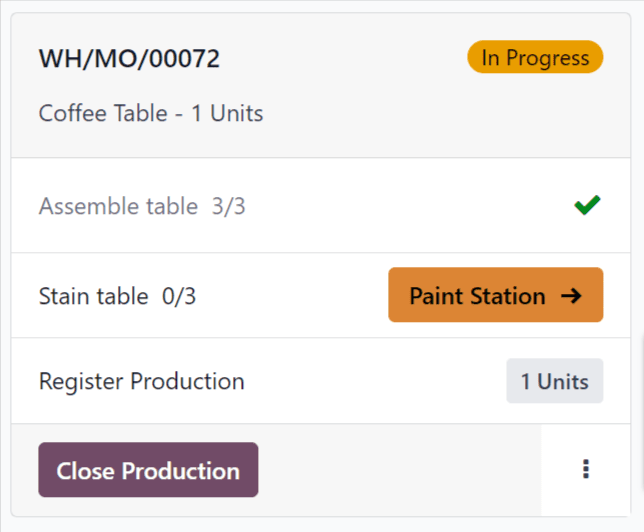

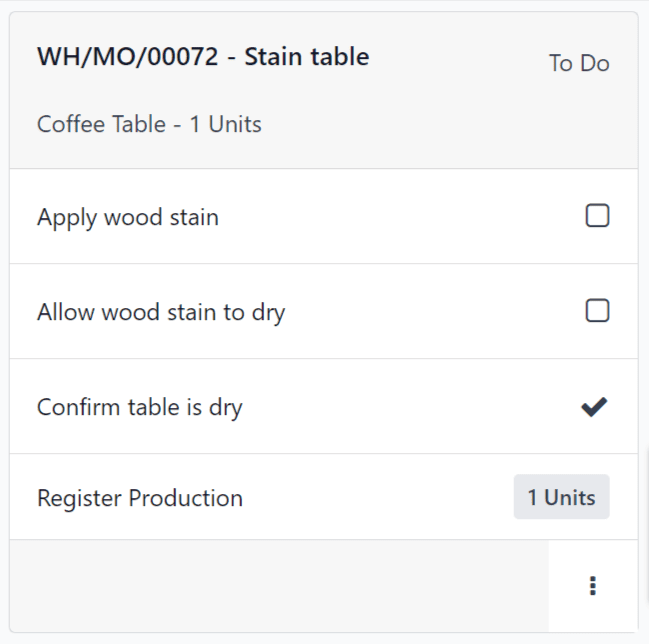

When accessed directly from a specific work order within an MO, Shop Floor defaults to the page for the work center where the work order is configured to be carried out. The page shows a card for the work order that displays the MO number, the product and number of units to be produced, and the steps required to complete the work order.

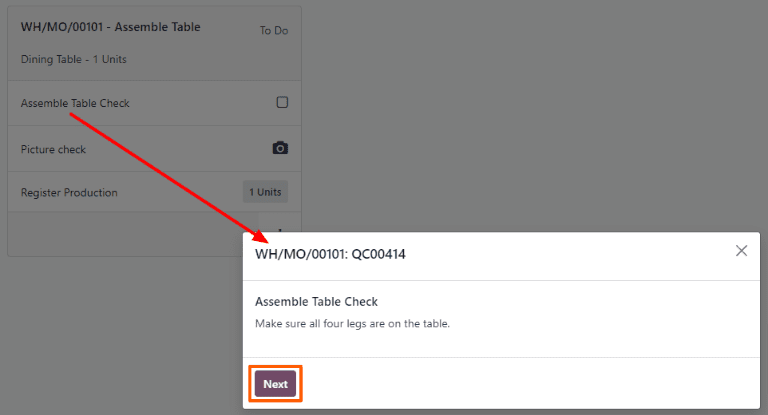

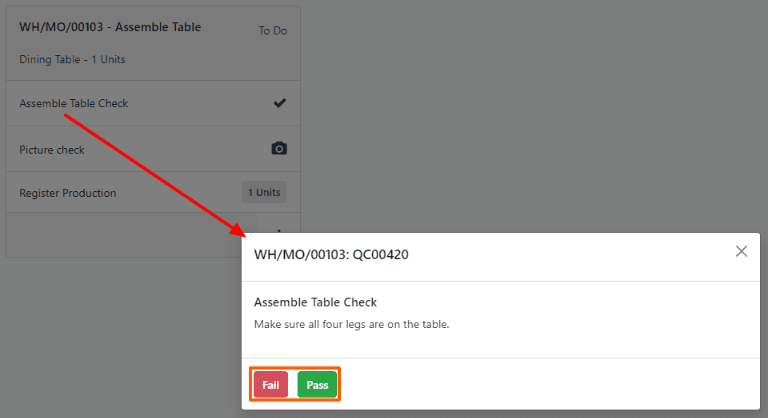

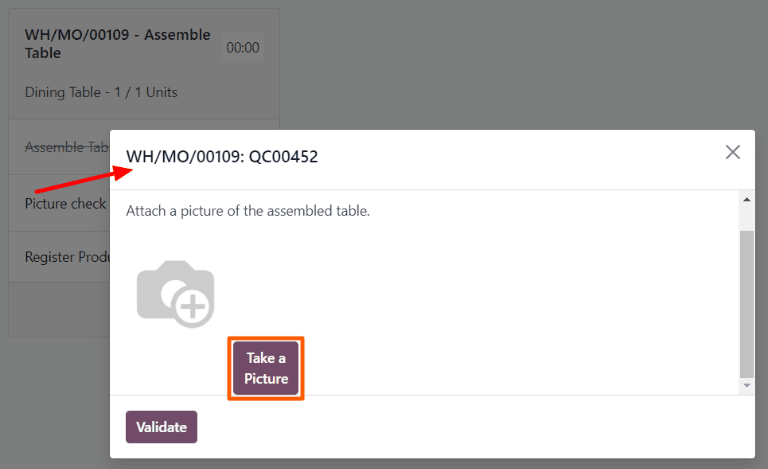

A work order is processed by completing each step listed on its card. This can be done by clicking on a step and following the instructions listed on the pop-up window that appears. Once the step is completed, click Next to move on to the next step, if any are required.

Alternatively, work order steps can be completed by clicking the checkbox that appears on the right side of the step’s line on the work order card. When using this method, the step is automatically marked as completed, without a pop-up window appearing.

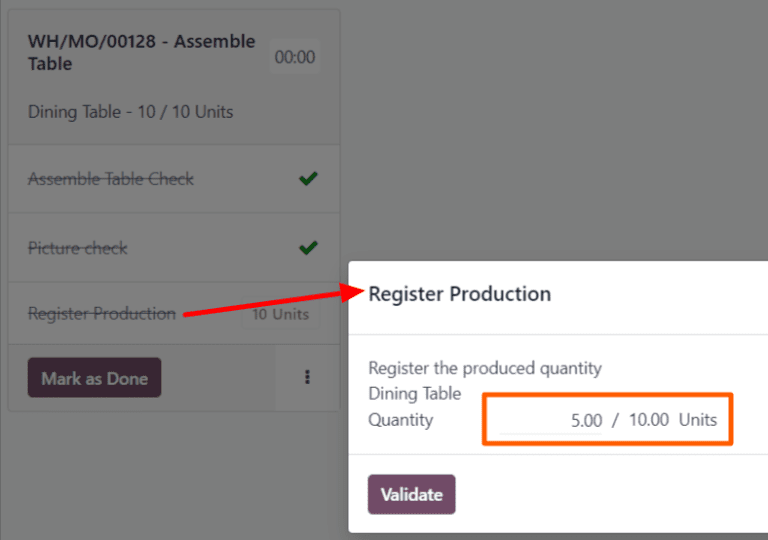

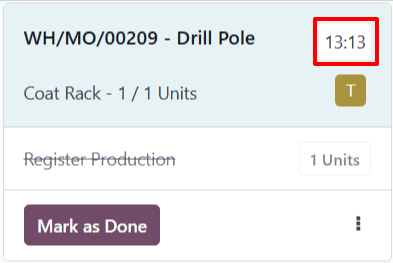

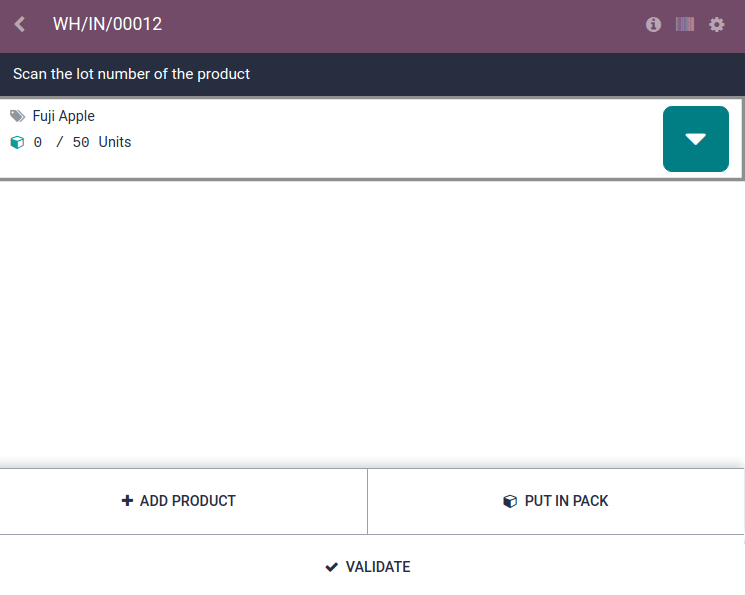

The final step on a work order card is titled Register Production. This step is used to register the number of product units that were produced. If the number produced is equal to the number that the MO was created for, click the # Units button on the right side of the line to automatically register that number as the quantity produced.

If a different number must be entered, click the Register Production step to open a pop-up window. Enter the number of units produced in the Units field, and then click Validate to register that number.

Note

The Register Production step appears on every work order card. It must be completed for the first work order that is processed. After doing so, the step appears as already completed for each remaining work order in the MO.

After completing all of the steps for a work order, a button appears on the footer of the work order card. If any other work orders must be completed before the MO can be closed, the button is titled Mark as Done. If there are no additional work orders to complete, the button is titled Close Production.

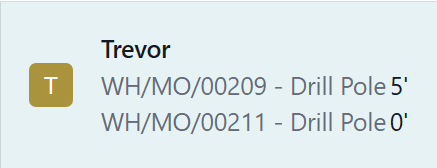

Clicking Mark as Done causes the work order card to fade away. Once it disappears completely, the work order’s status is marked as Finished on the MO, and the next work order appears in the Shop Floor module, on the page of the work center where it is configured to be carried out. Any additional work orders can be processed using the instructions detailed in this section.

Clicking Close Production causes the work order card to fade away. Once it disappears, the MO is marked as Done, and the units of the product that were produced are entered into inventory.

After clicking Mark as Done or Close Production, each button is replaced by an Undo button. Click the Undo button before the work order card fades away to keep the work order open.

Tip

This section details the basic workflow for processing an MO in the Shop Floor module. For a more in-depth explanation of the module and all of its features, please see the Shop Floor overview documentation.

On this page

Get Help

Contact Support Ask the Odoo Community

- User Docs

- Database management

- Developer

- Contributing

EN

Odoo 18

Two-step manufacturing

Odoo Manufacturing allows users to manufacture products using one, two, or three steps. When using two-step manufacturing, Odoo creates a manufacturing order (MO) and a pick components transfer, but does not generate a transfer for the movement of finished products into stock. Inventory counts still update based on the number of products manufactured, but the act of transferring them to and from inventory is not tracked.

Tip

The number of steps used in manufacturing is set at the warehouse level, allowing for each warehouse to use a different number of steps. To change the number of steps used for a specific warehouse, begin by navigating to Inventory ‣ Configuration ‣ Warehouses, and then select a warehouse from the Warehouses screen.

On the Warehouse Configuration tab, find the Manufacture radio input field, and select one of the three options: Manufacture (1 step), Pick components and then manufacture (2 steps), or Pick components, manufacture and then store products (3 steps).

Important

Products must be properly configured before they can be manufactured in Odoo. For details on how to do so, see the documentation on how to configure a product for manufacturing.

Create manufacturing order

To manufacture a product in Odoo Manufacturing, begin by navigating to Manufacturing ‣ Operations ‣ Manufacturing Orders, and then click New to create a new MO.

On the new MO, select the product to be produced from the Product drop-down menu. The Bill of Material field auto-populates with the associated Bill of Materials (BoM).

If a product has more than one BoM configured for it, the specific BoM can be selected in the Bill of Material field, and the Product field auto-populates with the associated product.

After a BoM has been selected, the Components and Work Orders tabs auto-populate with the components and operations specified on the BoM. If additional components or operations are required for the MO being configured, add them to the Components and Work Orders tabs by clicking Add a line.

Finally, click Confirm to confirm the MO.

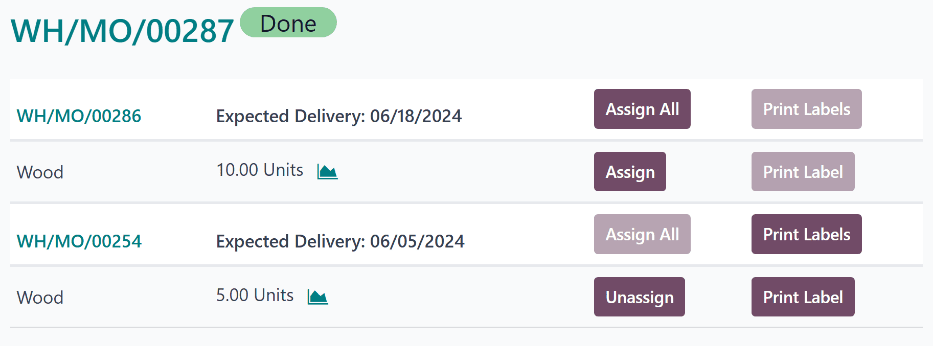

Process pick components transfer

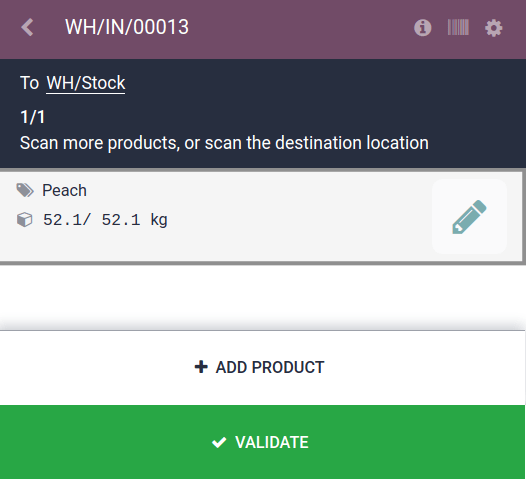

After confirming a two-step MO, a Transfers smart button appears at the top of the page. Click it to open the pick components transfer for the MO. This transfer is used to track the movement of components from the locations where they are stored to the location where they are used to manufacture the product.

After transferring the components out of their storage location, click Validate at the top of the transfer, followed by Apply on the Immediate Transfer? pop-up window that appears. Doing so marks the transfer as Done, and updates inventory counts to reflect the quantity of components transferred.

Finally, return to the MO by clicking the WH/MO/XXXXX breadcrumb at the top of the page.

Process manufacturing order

An MO is processed by completing all of the work orders listed under its Work Orders tab. This can be done on the MO itself, or from the work order tablet view.

Basic workflow

To complete work orders from the MO itself, begin by navigating to Manufacturing ‣ Operations ‣ Manufacturing Orders, and then select an MO.

On the MO page, select the Work Orders tab. Once work begins on the first work order that needs to be completed, click the Start button for that operation. Odoo Manufacturing then starts a timer that keeps track of how long the work order takes to complete.

When the work order is completed, click the Done button for that work order. Repeat the same process for each work order listed on the Work Orders tab.

After completing all of the work orders, click Produce All at the top of the screen to mark the MO as Done, and register the manufactured product(s) into inventory.

Shop Floor workflow

To complete the work orders for an MO using the Shop Floor module, begin by navigating to Manufacturing ‣ Operations ‣ Manufacturing Orders, and then select an MO.

On the MO, click on the Work Orders tab, and then select the ↗️ (square with arrow coming out of it) button on the line of the first work order to be processed. Doing so opens a Work Orders pop-up window, with details and processing options for the work order.

On the pop-up window, select the Open Shop Floor button at the top-left of the window to open the Shop Floor module.

When accessed directly from a specific work order within an MO, Shop Floor defaults to the page for the work center where the work order is configured to be carried out. The page shows a card for the work order that displays the MO number, the product and number of units to be produced, and the steps required to complete the work order.

A work order is processed by completing each step listed on its card. This can be done by clicking on a step and following the instructions listed on the pop-up window that appears. Once the step is completed, click Next to move on to the next step, if any are required.

Alternatively, work order steps can be completed by clicking the checkbox that appears on the right side of the step’s line on the work order card. When using this method, the step is automatically marked as completed, without a pop-up window appearing.

The final step on a work order card is titled Register Production. This step is used to register the number of product units that were produced. If the number produced is equal to the number that the MO was created for, click the # Units button on the right side of the line to automatically register that number as the quantity produced.

If a different number must be entered, click the Register Production step to open a pop-up window. Enter the number of units produced in the Units field, and then click Validate to register that number.

Note

The Register Production step appears on every work order card. It must be completed for the first work order that is processed. After doing so, the step appears as already completed for each remaining work order in the MO.

After completing all of the steps for a work order, a button appears on the footer of the work order card. If any other work orders must be completed before the MO can be closed, the button is titled Mark as Done. If there are no additional work orders to complete, the button is titled Close Production.

Clicking Mark as Done causes the work order card to fade away. Once it disappears completely, the work order’s status is marked as Finished on the MO, and the next work order appears in the Shop Floor module, on the page of the work center where it is configured to be carried out. Any additional work orders can be processed using the instructions detailed in this section.

Clicking Close Production causes the work order card to fade away. Once it disappears, the MO is marked as Done, and the units of the product that were produced are entered into inventory.

After clicking Mark as Done or Close Production, each button is replaced by an Undo button. Click the Undo button before the work order card fades away to keep the work order open.

Tip

This section details the basic workflow for processing an MO in the Shop Floor module. For a more in-depth explanation of the module and all of its features, please see the Shop Floor overview documentation.

On this page

Get Help

Contact Support Ask the Odoo Community

- User Docs

- Database management

- Developer

- Contributing

EN

Odoo 18

Three-step manufacturing

Odoo Manufacturing allows users to manufacture products using one, two, or three steps. When using three-step manufacturing, Odoo creates a pick components transfer, a manufacturing order (MO), and a store finished products transfer, and updates inventory counts based on the number of components removed, and finished products created.

Tip

The number of steps used in manufacturing is set at the warehouse level, allowing for each warehouse to use a different number of steps. To change the number of steps used for a specific warehouse, begin by navigating to Inventory ‣ Configuration ‣ Warehouses, and then select a warehouse from the Warehouses screen.

On the Warehouse Configuration tab, find the Manufacture radio input field, and select one of the three options: Manufacture (1 step), Pick components and then manufacture (2 steps), or Pick components, manufacture and then store products (3 steps).

Important

Products must be properly configured before they can be manufactured in Odoo. For details on how to do so, see the documentation on how to configure a product for manufacturing.

Create manufacturing order

To manufacture a product in Odoo Manufacturing, begin by navigating to Manufacturing ‣ Operations ‣ Manufacturing Orders, and then click New to create a new MO.

On the new MO, select the product to be produced from the Product drop-down menu. The Bill of Material field auto-populates with the associated Bill of Materials (BoM).

If a product has more than one BoM configured for it, the specific BoM can be selected in the Bill of Material field, and the Product field auto-populates with the associated product.

After a BoM has been selected, the Components and Work Orders tabs auto-populate with the components and operations specified on the BoM. If additional components or operations are required for the MO being configured, add them to the Components and Work Orders tabs by clicking Add a line.

Finally, click Confirm to confirm the MO.

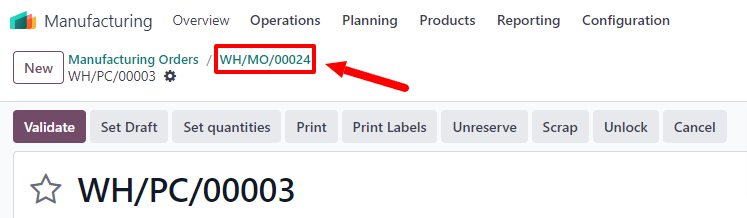

Process pick components transfer

After confirming a three-step MO, a Transfers smart button appears at the top of the page. Click it to be taken to the Transfers page for the MO. The page lists two transfers: WH/PC/XXXXX (the pick components transfer), and WH/SFP/XXXXX (the store finished products transfer).

Select WH/PC/XXXXX to open the pick components transfer for the MO. This transfer is used to track the movement of components from the locations where they are stored to the location where they are used to manufacture the product.

After transferring the components out of their storage location, click Validate at the top of the transfer, followed by Apply on the Immediate Transfer? pop-up window that appears. Doing so marks the transfer as Done, and updates inventory counts to reflect the quantity of components transferred.

Finally, return to the MO by clicking the WH/MO/XXXXX breadcrumb at the top of the page.

Process manufacturing order

An MO is processed by completing all of the work orders listed under its Work Orders tab. This can be done on the MO itself, or from the work order tablet view.

Basic workflow

To complete work orders from the MO itself, begin by navigating to Manufacturing ‣ Operations ‣ Manufacturing Orders, and then select a manufacturing order.

On the MO page, select the Work Orders tab. Once work begins on the first work order that needs to be completed, click the Start button for that work order. Odoo Manufacturing then starts a timer that keeps track of how long the work order takes to complete.

When the work order is completed, click the Done button for that work order. Repeat the same process for each work order listed on the Work Orders tab.

After completing all of the work orders, click Produce All at the top of the screen to mark the MO as Done, and register the manufactured product(s) into inventory.

Shop Floor workflow

To complete the work orders for an MO using the Shop Floor module, begin by navigating to Manufacturing ‣ Operations ‣ Manufacturing Orders, and then select an MO.

On the MO, click on the Work Orders tab, and then select the ↗️ (square with arrow coming out of it) button on the line of the first work order to be processed. Doing so opens a Work Orders pop-up window, with details and processing options for the work order.

On the pop-up window, select the Open Shop Floor button at the top-left of the window to open the Shop Floor module.

When accessed directly from a specific work order within an MO, Shop Floor defaults to the page for the work center where the work order is configured to be carried out. The page shows a card for the work order that displays the MO number, the product and number of units to be produced, and the steps required to complete the work order.

A work order is processed by completing each step listed on its card. This can be done by clicking on a step, and following the instructions listed on the pop-up window that appears. Once the step is completed, click Next to move on to the next step, if any are required.

Alternatively, work order steps can be completed by clicking the checkbox that appears on the right side of the step’s line on the work order card. When using this method, the step is automatically marked as completed, without a pop-up window appearing.

The final step on a work order card is titled Register Production. This step is used to register the number of product units that were produced. If the number produced is equal to the number that the MO was created for, click the # Units button on the right side of the line to automatically register that number as the quantity produced.

If a different number must be entered, click the Register Production step to open a pop-up window. Enter the number of units produced in the Units field, and then click Validate to register that number.

Note

The Register Production step appears on every work order card. It must be completed for the first work order that is processed. After doing so, the step appears as already completed for each remaining work order in the MO.

After completing all of the steps for a work order, a button appears on the footer of the work order card. If any other work orders must be completed before the MO can be closed, the button is titled Mark as Done. If there are no additional work orders to complete, the button is titled Close Production.

Clicking Mark as Done causes the work order card to fade away. Once it disappears completely, the work order’s status is marked as Finished on the MO, and the next work order appears in the Shop Floor module, on the page of the work center where it is configured to be carried out. Any additional work orders can be processed using the instructions detailed in this section.

Clicking Close Production causes the work order card to fade away. Once it disappears, the MO is marked as Done, and the units of the product that were produced are entered into inventory.

After clicking Mark as Done or Close Production, each button is replaced by an Undo button. Click the Undo button before the work order card fades away to keep the work order open.

Tip

This section details the basic workflow for processing an MO in the Shop Floor module. For a more in-depth explanation of the module and all of its features, please see the Shop Floor overview documentation.

Process finished product transfer

After completing the MO, return to the order’s Transfers page by clicking the Transfers button at the top of the order. This time, select WH/SFP/XXXXX to open the store finished products transfer. This transfer is used to track the movement of finished products from the location where they were manufactured to the location where they are stored.

After transferring the finished products to their storage location, click Validate at the top of the transfer, followed by Apply on the Immediate Transfer? pop-up window that appears. Doing so marks the transfer as Done, and updates inventory counts to reflect the quantity of finished products transferred.

On this page

Get Help

Contact Support Ask the Odoo Community

- User Docs

- Database management

- Developer

- Contributing

EN

Odoo 18

Manufacturing order costs

The ability to accurately calculate the cost of manufacturing a product is critical when determining product profitability. Odoo’s Manufacturing app simplifies this calculation by automatically calculating the cost to complete each manufacturing order (MO), as well as the average production cost of a product, based on all completed MOs.

Important

Odoo’s Manufacturing app distinguishes between the MO cost and the real cost of an MO.

The MO cost represents how much it should cost to complete an MO, based on the configuration of the product’s bill of materials (BoM). This takes into account the cost and quantity of components, as well as the cost of completing the necessary operations.

The real cost represents how much it actually costs to complete the MO. A few factors can cause the real cost to differ from the MO cost. For example, an operation may take longer to complete than estimated, a greater component quantity might be needed than was specified on the BoM, or the price of components may change during manufacturing.

Cost configuration

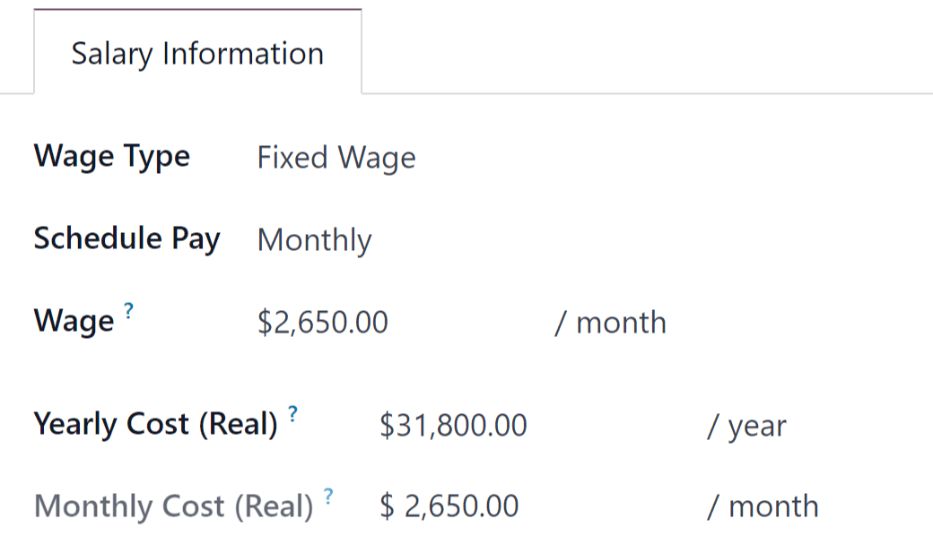

Odoo computes MO costs based on the configuration of the BoM used to manufacture a product. This calculation includes the cost and quantity of components and operations listed on the BoM, in addition to the operating costs of the work centers where those operations are carried out, and the amount paid to each employee who works on an operation.

Component cost

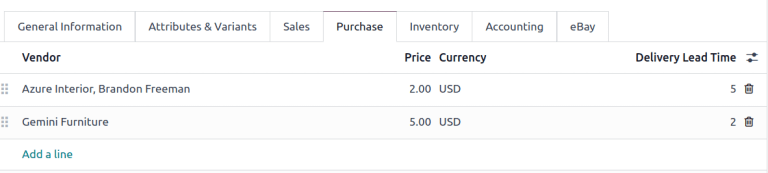

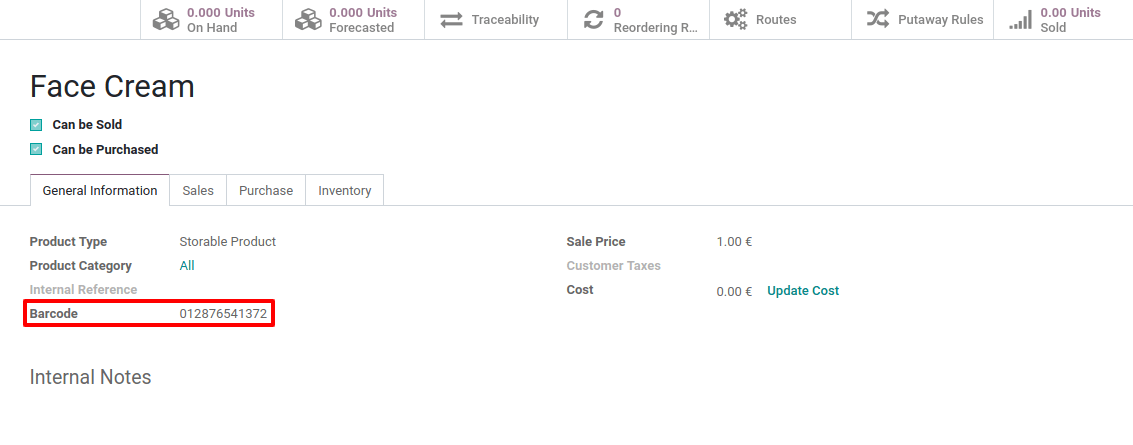

Component cost is calculated automatically, based on the average purchase cost of a component across all purchase orders (POs). To view a component’s cost, navigate to Inventory app –> Products –> Products, and select a component product. The cost is displayed in the Cost field of the General Information tab, on the component’s product form.

It is possible to set the cost of a component manually, by clicking the Cost field on the component’s product form and entering a value. However, any future POs for the component override a manually entered value, resetting the Cost field back to an automatically computed value.

Work center cost

To set the operating cost for a specific work center, navigate to Manufacturing app ‣ Configuration ‣ Work Centers, and select a work center.

To set the cost of operating the work center for one hour, enter a value in the per workcenter field, located beside the Cost per hour section on the work center’s General Information tab.

To set the hourly cost of each employee that operates the work center, enter a value in the per employee field, located beside the Cost per hour section on the work center’s General Information tab. For example, if 25.00 is entered in the per employee field, it costs $25.00 per hour for each employee working at the work center.

Important

The value entered in the per employee field is only used to calculate the MO cost, which is the estimated cost of completing the MO.

The actual cost of completing the MO is represented by the real cost. Instead of using the value entered in the per employee field, the real cost is calculated using the hourly cost specific to each employee.

For example, if the per employee cost of a work center is ‘$50.00’, and an employee with an hourly cost of ‘$60.00’ completes a work order there, the MO cost (estimated) is calculated using the $50/hr cost, while the real cost is calculated using the $60/hr cost.

See the employee cost section below for information on how to set the cost for specific employees.

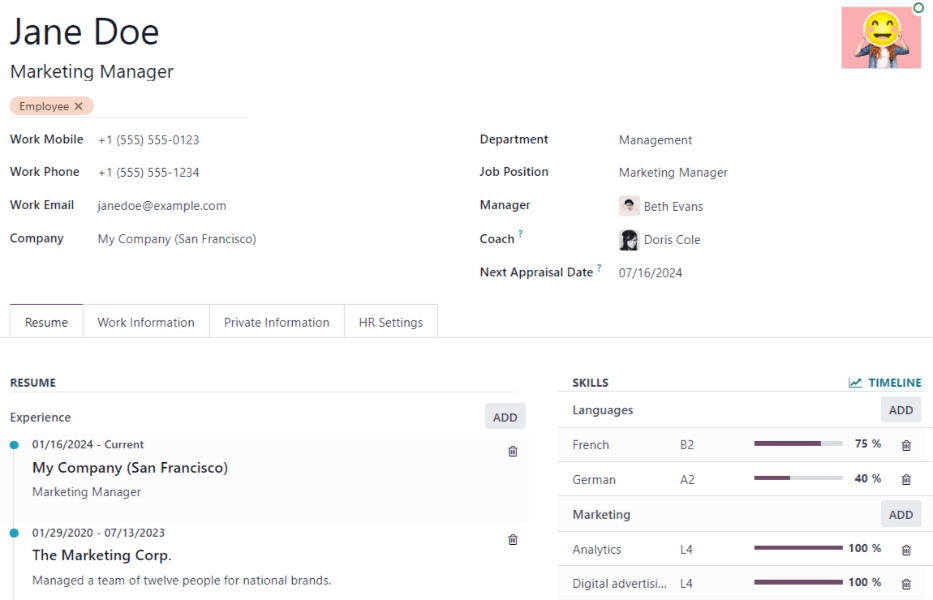

Employee cost

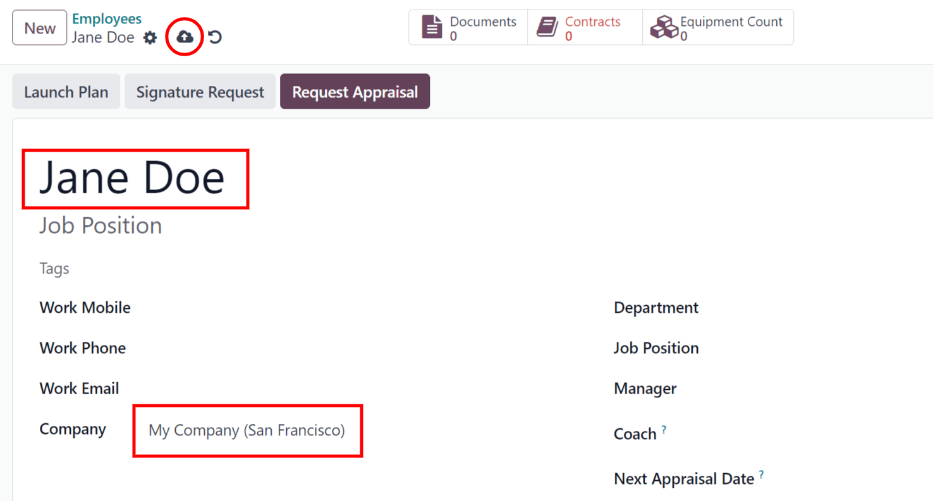

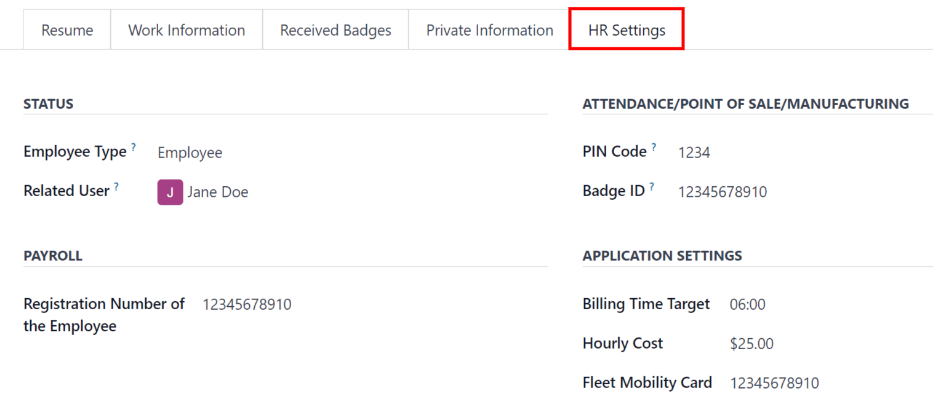

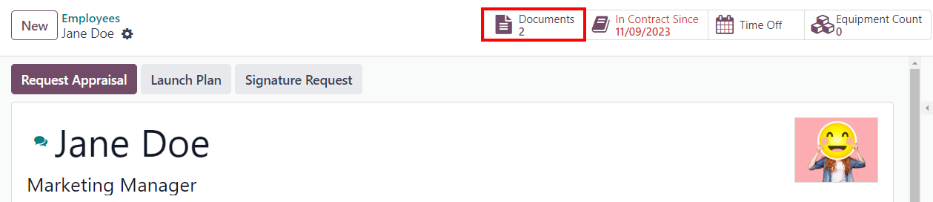

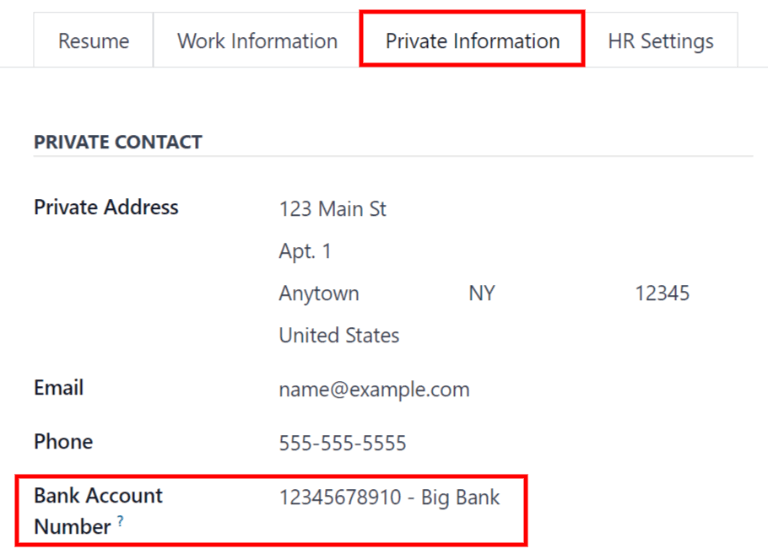

To set the hourly cost for a specific employee, navigate to the Employees app, and select an employee. On the employee’s form, select the Settings tab, and enter the employee’s rate in the Hourly Cost field of the Application Settings section.

Important

As detailed in the work center cost section above, the value entered in the Hourly Cost field on the employee’s form is used to calculate the real cost of an MO. The estimated cost of an MO, referred to as the MO cost, uses the per employee cost set on each work center’s form.

BoM configuration

Configuring a BoM so Odoo can accurately calculate the cost of MOs that use it requires two steps. First, components must be added, and the required quantity specified. Second, operations must be added, along with the work centers where they are carried out.

Begin by navigating to Manufacturing app ‣ Products ‣ Bills of Materials. Select a BoM, or create a new one by clicking New.

In the Components tab of the BoM form, add each component by clicking Add a line, selecting the component from the drop-down menu in the Component column, and entering the quantity in the Quantity column.

In the Operations tab, add an operation by clicking Add a line to open the Create Operations pop-up window. Enter a title for the operation in the Operation field.

Select the Work Center where the operation is carried out. Then, add a Default Duration, which is the estimated amount of time the operation takes to complete.

By default, the Duration Computation field is set to Set duration manually, which means that the number entered in Default Duration field is always used as the expected duration of the operation.

Selecting Compute based on tracked time causes Odoo to automatically compute the Default Duration based on a certain number of work orders, which is set in the Based on field. Before there are work orders to compute this duration, the value in the Default Duration field is used instead.

The hourly cost of operating the work center, and the duration of the operation, are used to calculate the operation’s cost.

Finally, click Save & Close to add the operation to the BoM, and close the Create Operations pop-up window. Alternatively, click Save & New to add the operation to the BoM, and open a blank Create Operations pop-up window to add another operation.

See also

For a full overview of BoM configuration, see the documentation on bills of materials.

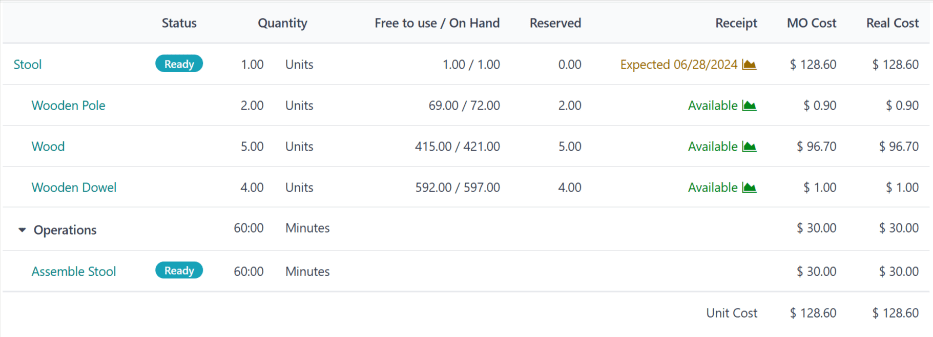

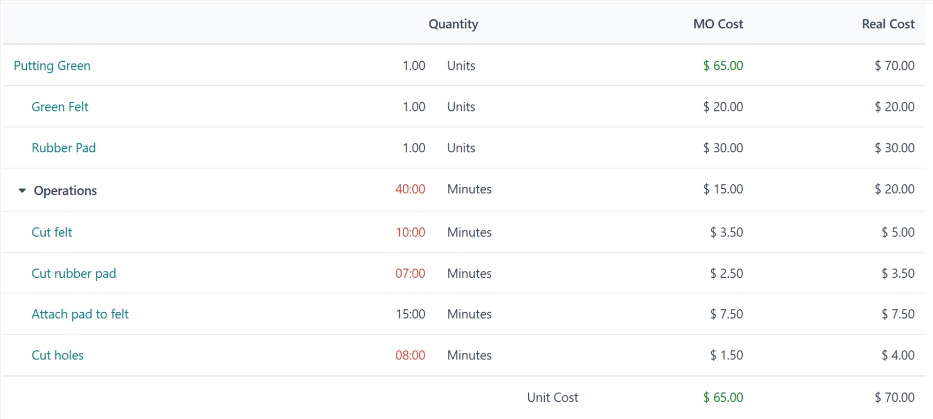

MO overview

Each MO has an overview page, which lists a variety of information about the MO, including MO cost and real cost. To view the overview for an MO, navigate to Manufacturing app ‣ Operations ‣ Manufacturing Orders, and select an MO. Then, click the Overview smart button at the top of the MO.

Both the MO cost and real cost take into account the cost and quantity of components, as well as the cost of completing each work order. The overview page lists a row for each of these values, with the sum of them listed at the bottom of the MO Cost and Real Cost columns.

Before work begins on an MO, the MO Cost and Real Cost columns display the same costs. This is the estimated cost of completing the MO.

However, once work commences, the values in the Real Cost column may begin to diverge from the values in the MO Cost column. This happens if a different component quantity is used than was listed on the MO, the duration of a work order is different than expected, or the hourly cost of the employee performing a work order differs from the employee cost set on the work center.

Once the MO has been completed by clicking Produce All, the values in the MO Cost column update to match those displayed in the Real Cost column.

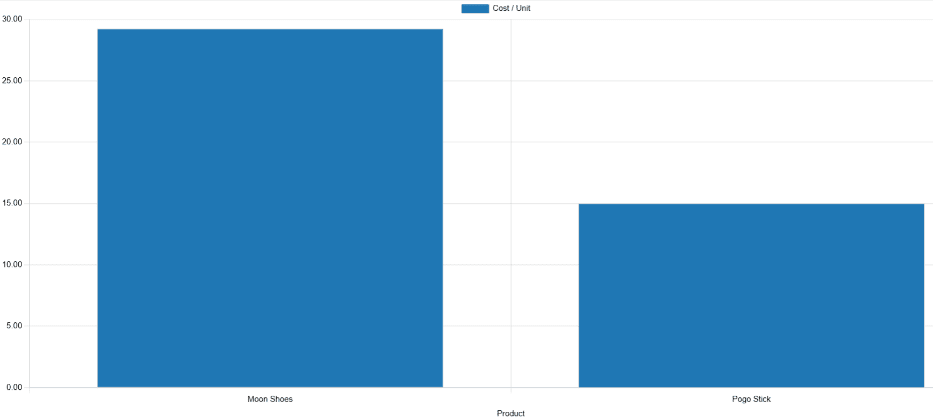

Average manufacturing cost

In addition to the cost of each individual MO for a product, Odoo also tracks the average cost of manufacturing the product, taking into account the cost of every completed MO. To view this, navigate to Inventory app ‣ Products ‣ Products, and select a product.

The manufacturing cost of the product is displayed per unit of measure in the Cost field, located in the General Information tab. The value continues to update as the costs of additional MOs are factored into the average cost.

To the right of the Cost field is a Compute Price from BoM button, which only appears for products with at least one BoM. Click this button to reset the cost of the product to the expected cost, which only takes into account the components and operations listed on the BoM.

Important

Be aware that clicking Compute Price from BoM does not set the price permanently. The cost continues to update based on the average of the BoM price and the real cost of any future MOs.

Example workflow: manufacturing cost

Golf product manufacturer Fairway Fields produces a variety of golf products, including an indoor putting green. They have configured a BoM for the putting green, so Odoo automatically calculates the manufacturing cost of each putting green MO.

The BoM lists two components:

- One unit of green felt, which costs $20.00.

- One unit of a rubber pad, which costs $30.00.

The BoM also lists four operations, all of which are carried out at Assembly Station 1, which has an hourly operating cost of $30.00. Those operations are as follows:

- Cut felt: default duration of seven minutes, for a total cost of $3.50.

- Cut rubber pad: default duration of five minutes, for a total cost of $2.50.

- Attach pad to felt: default duration of 15 minutes, for a total cost of $7.50.

- Cut holes: default duration of three minutes, for a total cost of $1.50.

Altogether, the components required to produce one putting green cost $50.00, and the operations required cost $15.00, for a total manufacturing cost of $65.00. This cost is reflected in the Cost field on the putting green’s product form.

Fairway Fields confirms an MO for one putting green. Before manufacturing starts, the MO overview lists a cost of $65.00 in both the MO Cost and Real Cost fields.

Manufacturing begins, and the operations take ten minutes longer than expected, for a total manufacturing time of 40 minutes. This deviation from the BoM is reflected on the MO overview, which now lists a Real Cost of $70.00.

Once manufacturing is finished, and the MO is marked as Done, the MO overview updates again, so the values in the MO Cost and Real Cost columns match, each displaying a value of $70.00.

On the putting green’s product page, the Cost field now displays a cost of $67.50, the average of the original cost of $65.00 and the real cost of $70.00 from the MO.

On this page

Get Help

Contact Support Ask the Odoo Community

- User Docs

- Database management

- Developer

- Contributing

EN

Odoo 18

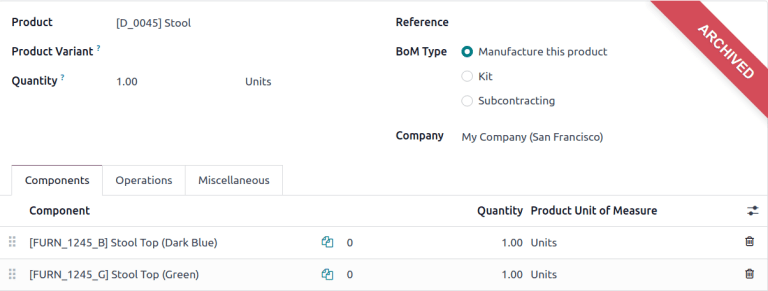

Managing BoMs for product variants

Odoo allows one bill of materials (BoM) to be used for multiple variants of the same product. Having a consolidated BoM for a product with variants saves time by preventing the need to manage multiple BoMs.

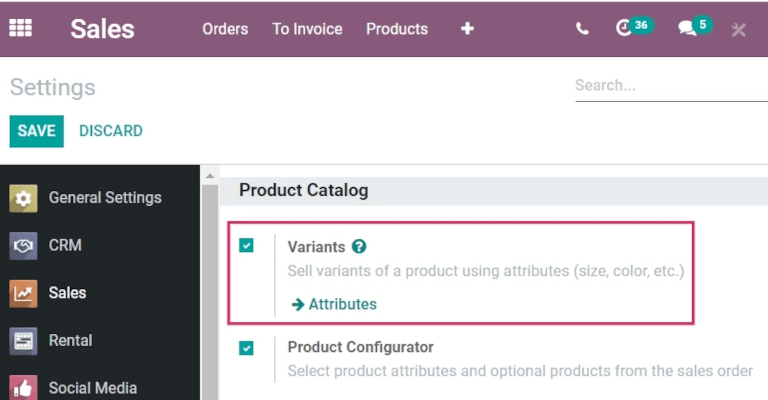

Activate product variants

To activate the product variants feature, navigate to Inventory app ‣ Configuration ‣ Settings, and scroll down to the Products section. Then, click the checkbox to enable the Variants option. After that, click Save to apply the setting.

For more information on configuring product variants, refer to the product variants documentation.

Create custom product attributes

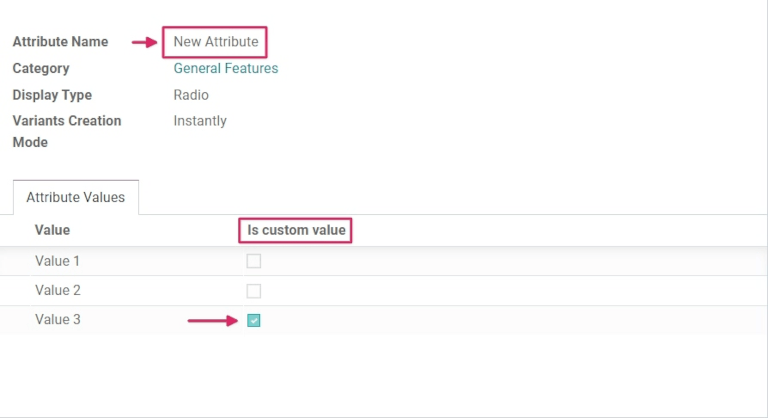

Once the product variants feature is activated, create and edit product attributes on the Attributes page.

The Attributes page is accessible either from Inventory app ‣ Configuration ‣ Settings by clicking the Attributes button, or by clicking Inventory app ‣ Configuration ‣ Attributes.

Once on the Attributes page, either click into an existing attribute, or click Create to create a new one. Clicking Create reveals a new, blank form for customizing an attribute. For an existing attribute, click Edit on its form to make changes.

Assign an Attribute Name, and choose a category from the Category field’s drop-down menu. Then, select the desired options next to the Display Type and Variants Creation Mode fields. Once the desired options are selected, click Add a line under the Attribute Values tab to add a new value.

Tip

Included on the Value row is a Is custom value checkbox. If selected, this value will be recognized as a custom value, which allows customers to type special customization requests upon ordering a custom variant of a product.

Example

Once all desired Values have been added, click Save to save the new attribute.

Add product variants on the product form

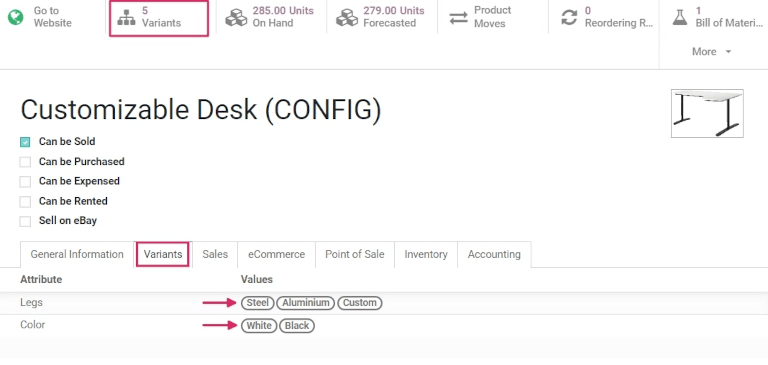

Created attributes can be applied on specific variants for particular products. To add product variants to a product, navigate to the product form by going to Inventory app ‣ Products ‣ Products. To make changes to the product, click Edit. Then, click the Variants tab.

Under the Attribute header, click Add a line to add a new attribute, and select one to add from the drop-down menu.

Then, under the Values header, click the drop-down menu to choose from the list of existing values. Click on each desired value to add them, and repeat this process for any additional attributes that should be added to the product.

Once finished, click Save to save changes.

Tip

BoM products with multiple variants that are manufactured in-house should either have a 0,0 reordering rule set up, or have their replenishment routes set to Replenish on Order (MTO).

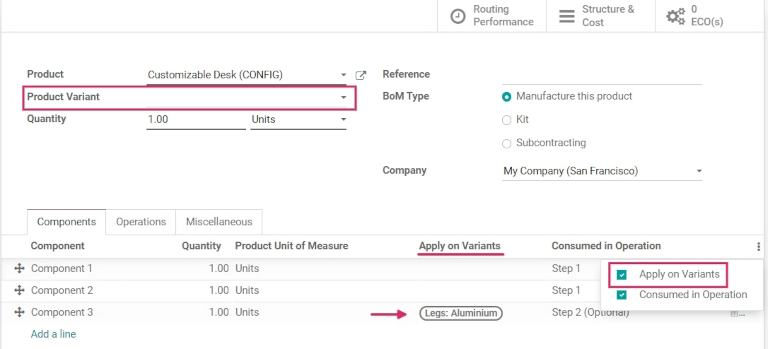

Apply BoM components to product variants

Next, create a new BoM. Or, edit an existing one, by going to Manufacturing app ‣ Products ‣ Bills of Materials. Then, click Create to open a new Bills of Materials form to configure from scratch.

Add a product to the BoM by clicking the drop-down menu in the Product field and selecting the desired product.

Then, add components by clicking Add a line under the Component section of the Components tab, and choosing the desired components from the drop-down menu.

Choose the desired values in the Quantity and Product Unit of Measure columns. Then, choose the desired values in the Apply on Variants column.

Note

The Apply on Variants option to assign components to specific product variants on the BoM is available once the Variants setting is activated from the Inventory application. If the Apply on Variants field is not immediately visible, activate it from the additional options menu (three-dots icon, to the right of the header row).

Each component can be assigned to multiple variants. Components with no variants specified are used in every variant of the product. The same principle applies when configuring operations and by-products.

When defining variant BoMs by component assignment, the Product Variant field in the main section of the BoM should be left blank. This field is only used when creating a BoM specifically for one product variant.

When all desired configurations have been made to the BoM, click Save at the top of the form to save changes.

Tip

For components that only apply for specific variants, choose which operations the components should be consumed in. If the Consumed in Operation column is not immediately visible, activate it from the additional options menu (three-dots icon, to the right of the header row).

Sell and manufacture variants of BoM products

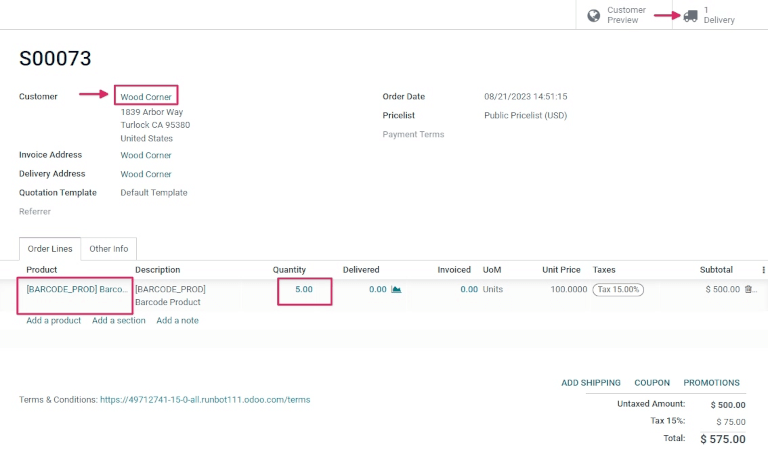

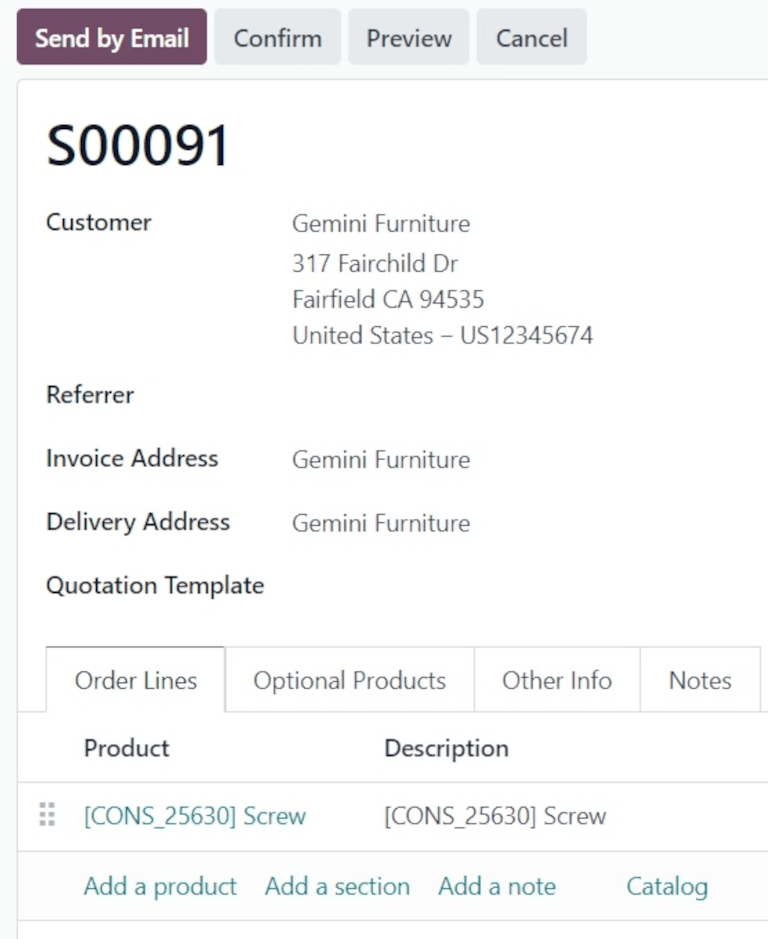

To sell and manufacture variants of BoM products to order, navigate to Sales app ‣ Create to create a new quotation.

Sell variant of BoM product

Once on the blank Quotation form, click the drop-down next to the Customer field to add a customer.

Then, under the Order Lines tab, click Add a product, and select the previously-created BoM product with variants from the drop-down menu. Doing so reveals a Configure a product pop-up.

From the pop-up window, click the desired attribute options to configure the correct variant of the product to manufacture. Then, click the green + or - icons next to the 1 to change the quantity to sell and manufacture, if desired.

Once all the specifications have been chosen, click Add. This will change the pop-up to a second Configure pop-up, where available optional products will appear, if they have been created previously.

Once ready, click Confirm to close the pop-up.

Then, click Save to save all changes, and click Confirm at the top of the Quotation form to create and confirm a new sales order (SO).

Manufacture variant of BoM product

Once the SO is confirmed, a Manufacturing smart button appears at the top of the SO form. Click the Manufacturing smart button to open the Manufacturing Order form.

On this form, under the Components tab, the appropriate components for the chosen variant are listed. And, depending on the variant, different components will be listed. To see any mandatory or optional Operation steps, click the Work Orders tab.

To enter the tablet view work order screen, click the tablet icon to the right of the row for the desired operation to be completed.

From the tablet view, click Mark as Done as the operation progresses to complete the operation steps.

Alternatively, click the Mark as Done button at the top of the manufacturing order form to complete the order.

Then, navigate back to the SO via the breadcrumbs at the top of the page.

Now that the product has been manufactured, click the Delivery smart button to deliver the product to the customer. From the Delivery Order form, click Validate, then click Apply to deliver the product.

To finish the sale, click back to the SO via the breadcrumbs at the top of the page again. Then, click Create Invoice followed by Create Invoice again to invoice the customer for the order.

On this page

Get Help

Contact Support Ask the Odoo Community

- User Docs

- Database management

- Developer

- Contributing

EN

Odoo 18

Kits

In Odoo, a kit is a type of bill of materials (BoM) that can be manufactured and sold. Kits are sets of unassembled components sold to customers. They may be sold as standalone products, and are also useful tools for managing more complex bills of materials (BoMs).

Note

To use, manufacture, and sell kits, both the Manufacturing and Inventory apps need to be installed.

Create the kit as a product

To use a kit as a sellable product, or as a component organization tool, the kit should first be created as a product.

To create a kit product, go to Inventory app ‣ Products ‣ Products, and then click New.

Then, assign a name to the new kit product. Next, set the kit’s product type depending on inventory tracking needs and accounting requirements. To do this, under the General Information tab, set the Product Type to Goods and either check the box next Track Inventory if inventory tracking is required, or leave it unchecked if inventory tracking for the kit is not necessary.

See also

Learn more about tracked versus untracked products.

The kit’s components must also be configured as products via Inventory app ‣ Products ‣ Products. These components require no specific configuration.

Untracked kit inventory setup details

Consider leaving tracking for the kit’s inventory untracked when the kit is used in other manufacturing processes or when tracking inventory for the kit itself is not needed.

- Recommended for Continental Accounting: If costs are expensed immediately upon purchase, then leaving the kit’s inventory as untracked is recommended.

- Replenishment via Components: Inventory count is managed at the component level, so reordering rules must be set to individual components.

- Selling & Stock Constraints: Kits cannot be sold if any required component is out of stock. Since availability depends on individual components, a sales order may appear valid, but delivery can be delayed if components are unavailable.

Tracked kit inventory setup details

Consider turning on tracking for the kit’s inventory when the kit is a tangible product or warehouse and inventory tracking is essential.

- Recommended for Angle-Saxon Accounting: If the Cost of Goods Sold (COGS) needs to be recorded in journals, then tracking the kit’s inventory is recommended.

- Component Purchase Constraints: Only the kit’s minimum required components can be added to an eCommerce cart unless the option to continue selling is disabled.

- No Kit Serial Numbers: Serial number tracking does not track the kit, only its shipped components.

- Reordering Rule Recommendation: Reordering rules should be set at the component-level.

- Stock Replenishment Recommendation: Stock replenishment should also be done at the component-level.

Kit setup similarities

Regardless of which setup is used, there are some similarities between the two options.

- No Kit-Level Stock Adjustments: Stock adjustments cannot be handled at the kit-level.

- Kit Value Does Not Change: The stock’s value is the same whether the kit’s is tracked.

- Kit Internal Transfers: An internal transfer for the kit breaks it into components.

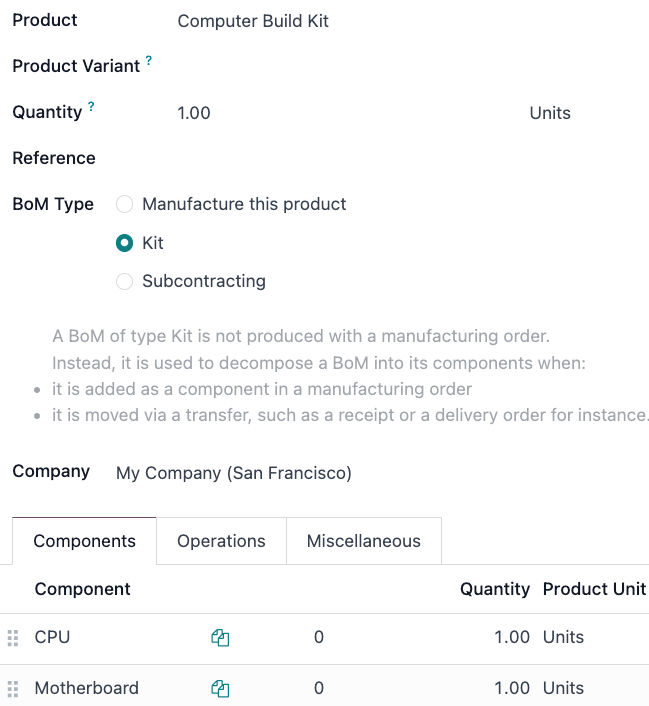

Set up the kit BoM

After fully configuring the kit product and its components, a new BoM can be created for the kit product.

To do so, go to Manufacturing app ‣ Products ‣ Bills of Materials, and then click New. Next to the Product field, click the drop-down menu to reveal a list of products, and then select the previously configured kit product.

Then, for the BoM Type field, click the Kit option. Finally, under the Components tab, click Add a line, and add each desired component, and specify their quantities under the Quantity column.

Once ready, click Save to save the newly created BoM.

If the kit is solely being used as a sellable product, then only components need to be added under the Components tab, and configuring manufacturing operations is not necessary.

Note

When a kit is sold as a product, it appears as a single line item on the quotation and sales order. However, on delivery orders, each component of the kit is listed.

Use kits to manage complex BoMs

Kits can also be used for complex BoMs. This method nests BoMs within other BoMs, organizing complex products while simplifying manufacturing by defining each procurement and production step separately.

Sublevel BoMs (subassemblies or semi-finished products) streamline these workflows, helping with traceability efforts.

See also

On this page

Get Help

Contact Support Ask the Odoo Community

- User Docs

- Database management

- Developer

- Contributing

EN

Odoo 18

Multilevel BoMs

Use a multilevel bill of materials (BoM) when a manufactured product is part of another assembly. This method nests BoMs within other BoMs, organizing complex products while simplifying manufacturing by defining each procurement and production step separately.

Sublevel BoMs (subassemblies or semifinished products) streamline these production workflows, and are beneficial when the subassembly is used across multiple finished products (meaning they’d appear on multiple top-level BoMs). The more complicated a product is to build or procure, the more value a multilevel BoM can provide. Because of this, component and subassembly replenishment planning is vital to ensuring multilevel BoMs run smoothly.

Why replenishment planning is important

Replenishment is critical for multilevel BoMs to prevent bottlenecks, manage lead times, and optimize inventory. Without it, missing components can halt production, delay orders, and increase costs. A well-planned replenishment strategy ensures just-in-time availability, automates procurement, balances stock levels, and keeps supply chains efficient. This minimizes delays, reduces manual effort, and ensures smooth manufacturing.

Manufacturing orders (MO)s that come from a BoM require all components to be available before the MO can be completed. The Component Status for that MO provides this information. Learn how to check an MO’s component status.

Create a multilevel BoM

To set up a multilevel BoM, the top-level product and sublevel products’s BoMs must be created. If starting from scratch, build the BoMs from the bottom up. Start with the lowest-level product BoMs, then include those products as components in higher-level BoMs.

Example

A printed circuit board (PCB) for a custom keyboard is composed of hundreds of electronic components, such as transistors, resistors, and capacitors. Instead of listing all of those components out, a sublevel product and BoM for a PCB is created, to track the quantities of transistors and other small components, without needing to overcrowd the top-level BoM for the custom keyboard by listing them. Instead, the custom keyboard’s BoM consists of an assortment of components and sublevel BoMs alike, like key caps, switches, the PCB, and keyboard plate.

Learn how to build a simple bill of materials. For the PCB, this would include the transistors, resistors, and other components.

After the sublevel products (like the PCB, key caps, and keyboard plate) are fully configured, create the top-level product by navigating to Manufacturing app ‣ Products ‣ Products, and then selecting New. From here, configure the product’s specifications as needed.

Once the top-level product (the keyboard) is configured, click the Bill of Materials smart button on the product form, and then select New to make a BoM for the top-level product. Add the sublevel products to this BoM, along with any other necessary components.

Manage production planning

The two options below are two of the best ways to manage manufacturing order automation for products with multilevel BoMs.

Note

Complex BoMs are specifically used to manage products that require manufactured components. If a BoM is being created to organize components or bundle sellable products, use a kit instead.

To automatically trigger manufacturing orders for sublevel products after confirming a manufacturing order for the main product, there are two options:

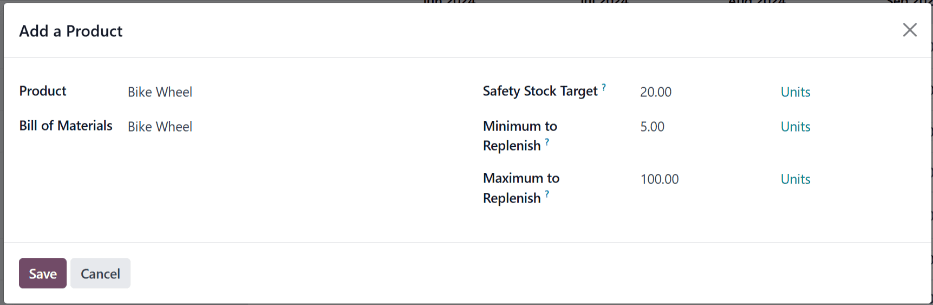

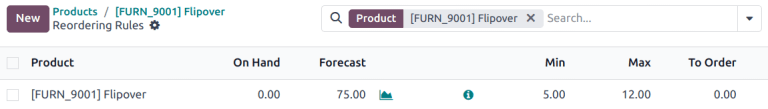

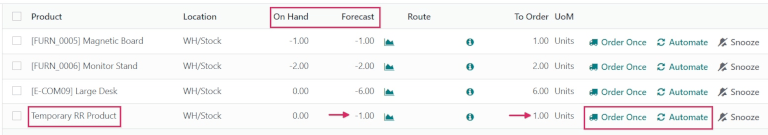

- Option 1 (recommended): Create Reordering Rules for the sublevel products and set both the minimum and maximum needed stock quantities to 0.

- Option 2: Activate the Replenish on Order (MTO) and Manufacture routes under the Inventory tab of the sublevel product’s product form.

See also

Option 1 is more flexible than Option 2 and is recommended. Reordering rules do not directly link demand to replenishment, allowing stock to be unreserved and reassigned as needed. The Replenish on Order (MTO) route, however, uniquely links sublevel and top-level products, reserving quantities for the confirmed top-level manufacturing order.

In both methods, sublevel products must be fully manufactured before starting the top-level product.

Multilevel BoM setup flow

The following section details how to set up multilevel BoMs, set the initial inventory, establish a 0/0/1 reordering rule (the recommended production plan), configure lead times, and set up production options.

Creating a 0/0/1 reordering rule for the sublevel products (minimum stock set at zero, maximum stock set at zero, reorder one automatically) regardless of whether they are a component or subassembly is the recommended approach for managing a multilevel BoM. This setup uses the Inventory, Manufacturing, and Purchase apps.

Important

This is only one example of how to set up a multilevel BoM in Odoo. Consider any unique circumstances that need to be addressed during the configuration, and make sure they are included in the setup. If any specific help is needed during setup, consider purchasing a success pack.

Create the BoMs

Follow the steps in the Create a multilevel BoM section to build the BoMs.

Make sure to build the multilevel BoM from the bottom up. Start by creating the lowest-level component products in Odoo, then the subassembly products that those are used for, then the BoM for that subassembly, and repeat until every level of the multilevel BoM is created.

Set the initial inventory

Note

If there’s no initial inventory to configure, then skip this section and begin configuring the procurement method for the multilevel BoM.

Update the quantity on hand for each of the products configured in the prior step (both components, subassemblies, and the final product). To do this, open the Inventory app, and then find the products with filters, the search bar, or scrolling, and then click on them to open their product form. From here, click the On Hand smart button, select the variant if that was configured, and then enter the quantity on hand.

See also

Configure the procurement method

Now it is time to pick the procurement method this multilevel BoM uses. The two options below are preferred, but unique circumstances may lead to another procurement method making more sense.

- Option 1 (recommended): Create Reordering Rules for the sublevel products and set both the minimum and maximum needed stock quantities to 0.

- Option 2: Activate the Replenish on Order (MTO) and Manufacture routes under the Inventory tab of the sublevel product’s product form.

See also

Reordering rules are recommended because they do not tie the manufactured product to a specific sales order, allowing that manufactured product to fulfill a different sales order if the original gets cancelled.

Making the product to order is not recommended because the manufactured product cannot be used to fulfill another sales order. However, this could be helpful if strict tracking is necessary for the business.

Enter vendor and manufacturing lead times

Vendor and manufacturing lead times are used by Odoo to coordinate production and procurement actions to fulfill orders on time. Set vendor lead times for components that are purchased. These can appear at any level in a multilevel BoM except the final product. Set manufacturing lead times for products that are built using a BoM. These can appear at any level in a multilevel BoM except the lowest level (when individual components are procured).

See also

Build out operations to handle the production flow

First, determine the current manufacturing flow for the business, then match the corresponding Odoo setup. The list below are only some of the configuration pieces that could be involved in this step.

- Manufacturing Steps: Consider how many manufacturing steps are taken (one-, two-, or three-step manufacturing).

- Work Centers: Decide if any work centers need to be configured.

- Master Production Schedule: If manually planned manufacturing orders are needed (e.g., to handle seasonal demand), make a master production schedule (MPS).

Tip

Manufacturing operations is an art and a science, so configuring an established flow into Odoo is the recommended approach for this step. Read more about manufacturing in Odoo

Configuration summary

At the end of this process, the multilevel BoM is configured, and the top-level product has its inventory counts, procurement method set, procurement lead times, and manufacturing operations configured. From here, sales orders can include the top-level product, automatic procurement through vendors or manufacturing can begin, the top-level product can be included in an eCommerce store.

See also

On this page

Get Help

Contact Support Ask the Odoo Community

- User Docs

- Database management

- Developer

- Contributing

EN

Odoo 18

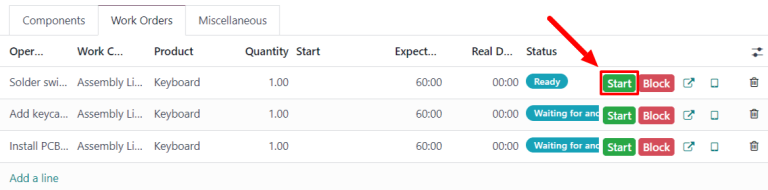

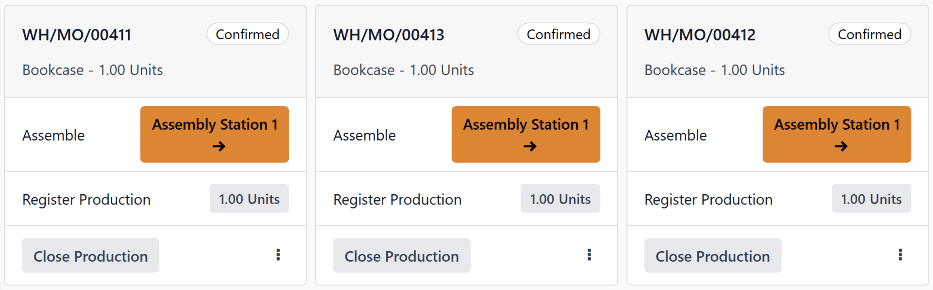

Manage work orders using work centers

Odoo Manufacturing allows for work orders to be carried out at specific work centers. When a manufacturing order is created for a product, any work orders listed in the Operations tab of the product bill of materials (BoM) will be automatically created as well and assigned to the specified work center. Work orders can be managed in the Manufacturing module by selecting Operations ‣ Work Orders.

In order to use work centers, the Work Orders feature must first be enabled. To do so, go to the Manufacturing module, select Configuration ‣ Settings, and activate the checkbox next to Work Orders. Work centers can then be created and managed by selecting Configuration ‣ Work Centers.

Create a work center

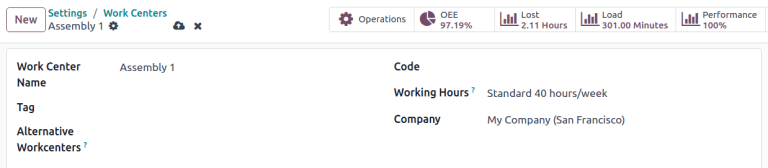

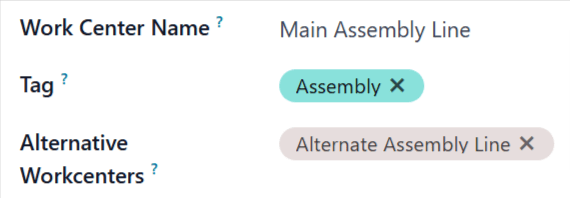

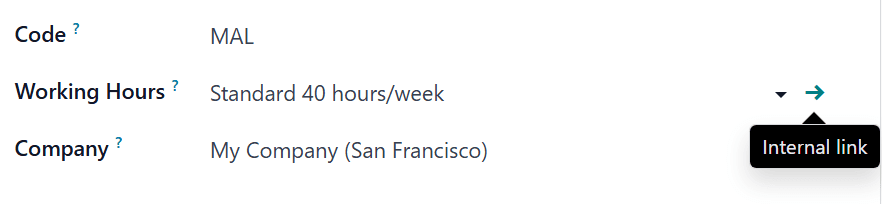

Within the Manufacturing module, select Configuration ‣ Work Centers ‣ Create. The work center form can then be filled out as follows:

- Work Center Name: give the work center a concise name that describes the type of operations it will be used for

- Alternative Workcenters: specify an alternative work center for operations to be carried out at if the main work center is not available

- Code: assign the work center a reference code

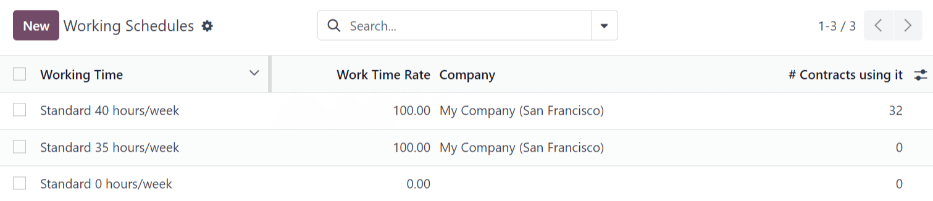

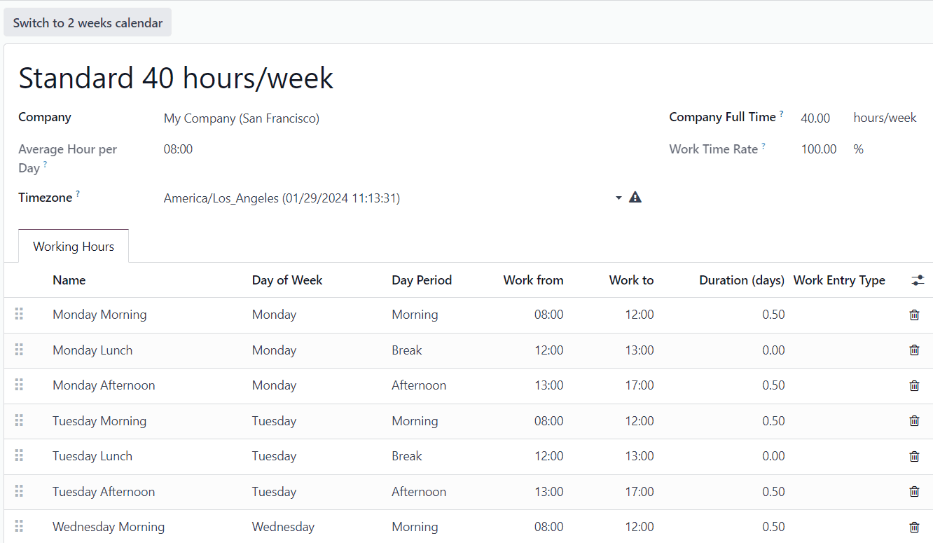

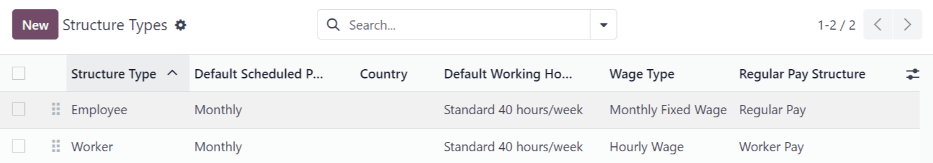

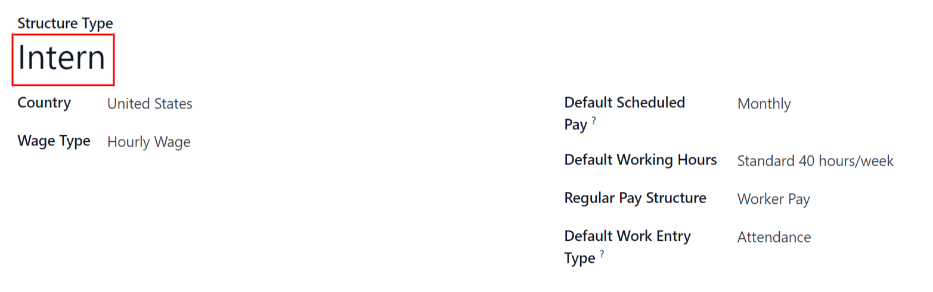

- Working Hours: define the number of hours that the work center can be in use each week

- Company: select the company that the work center belongs to

Set standards for work center productivity

The General Information tab on the work center form allows for productivity goals to be assigned to a work center:

- Time Efficiency: used to calculate the expected duration of a work order at the work center; for example, if a work order normally takes one hour and the efficiency is set to 200%, the work order will take 30 minutes

- Capacity: the number of products that can be processed at the work center simultaneously

- OEE Target: the target for efficiency at the work center

- Time before prod.: setup time required before work can commence

- Time after prod.: breakdown or cleanup time required after work is finished

- Cost per hour: the cost of operating the work center for one hour

- Analytic Account: the account where the cost of the work center should be recorded

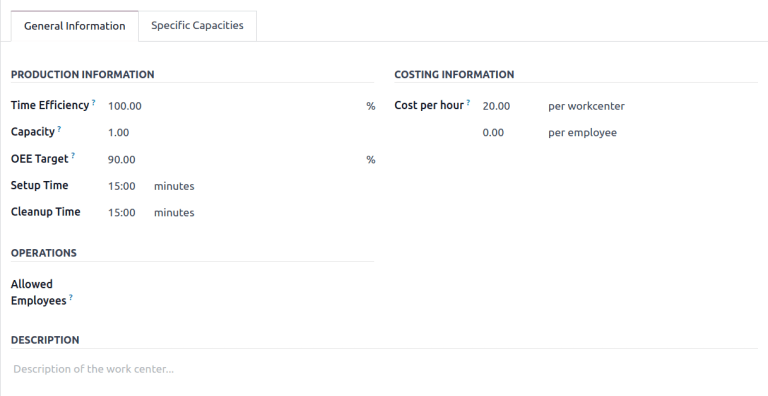

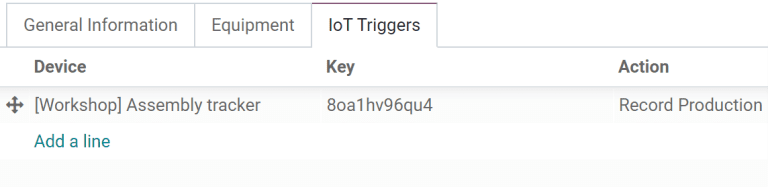

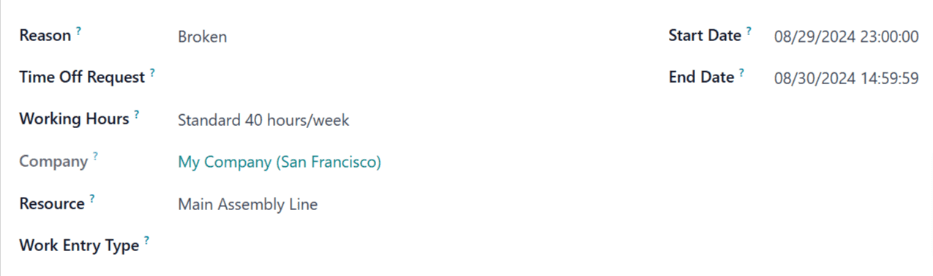

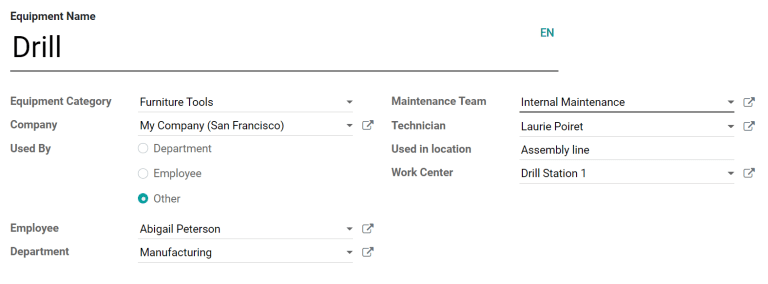

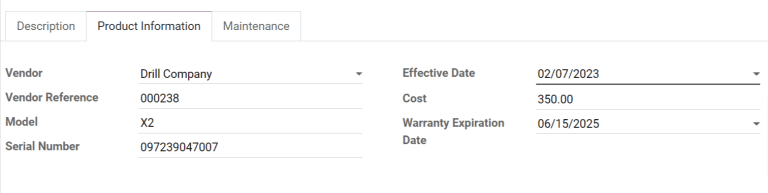

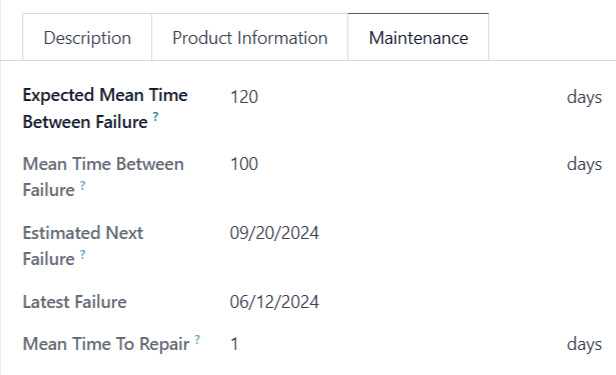

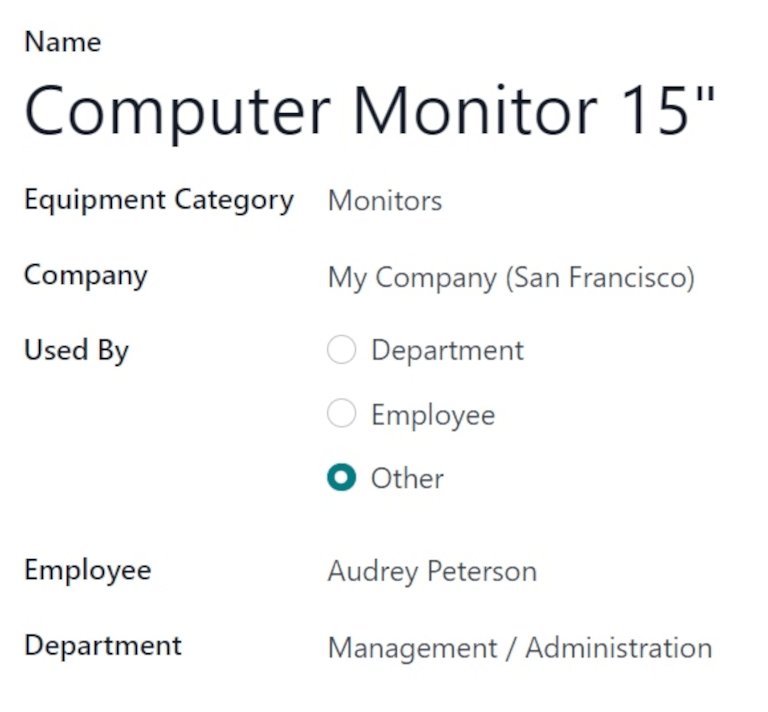

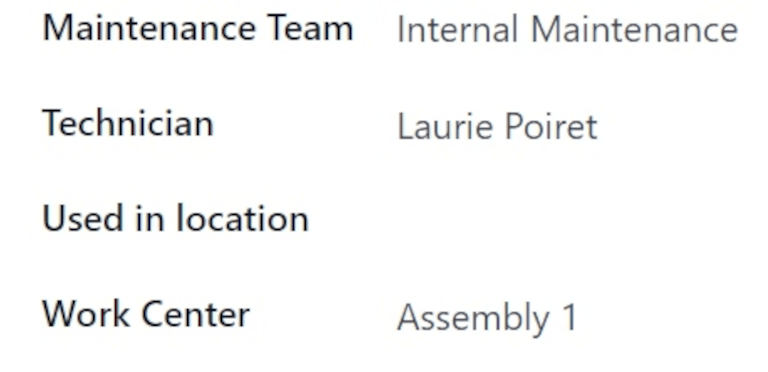

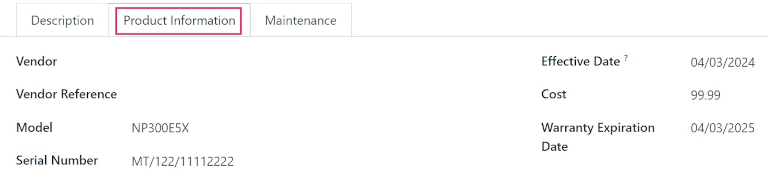

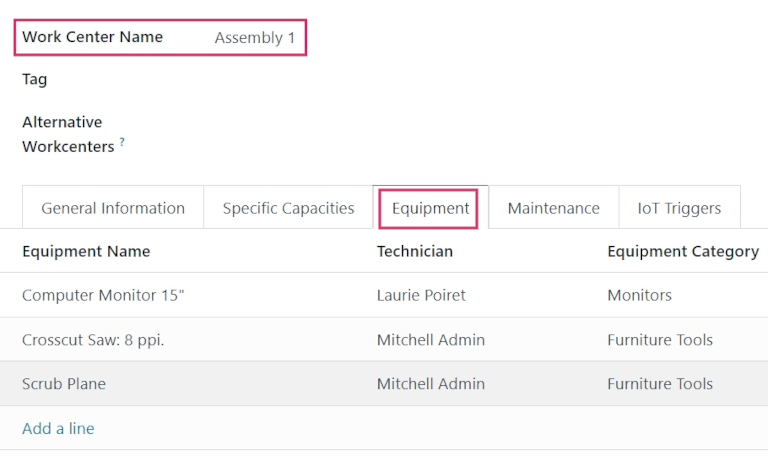

Assign equipment to a work center

Using the Equipment tab, it is possible for specific pieces of equipment to be assigned to a work center. The following information will be displayed for each piece of equipment added:

- Equipment Name: the name of the piece of equipment

- Technician: the technician responsible for servicing the equipment

- Equipment Category: the category the equipment belongs to

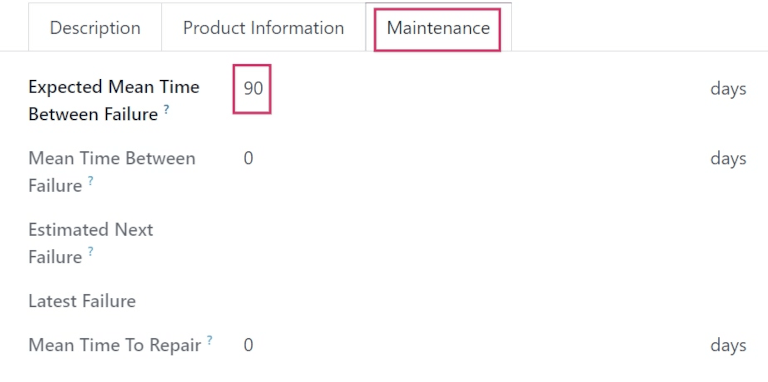

- MTBF: mean time between failures; the average time that the piece of equipment will operate before failing

- MTTR: mean time to recovery; the average time it takes for the equipment to become fully operational again

- Est. Next Failure: an estimate of when the next equipment failure will occur

Note

MTBF, MTTR, and Est. Next Failure are all calculated automatically based on past failure data, if any exists.

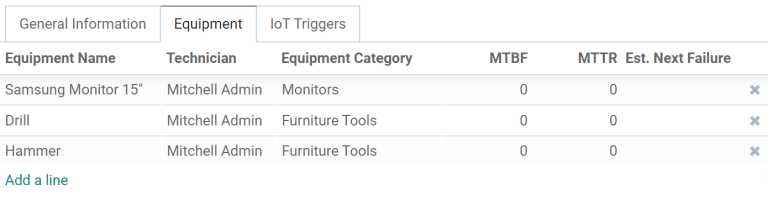

Integrate IoT devices

The IoT Triggers tab enables the integration of IoT devices with a work center:

- Device: specifies the IoT device to be triggered

- Key: the security key for the device

- Action: the IoT device action triggered

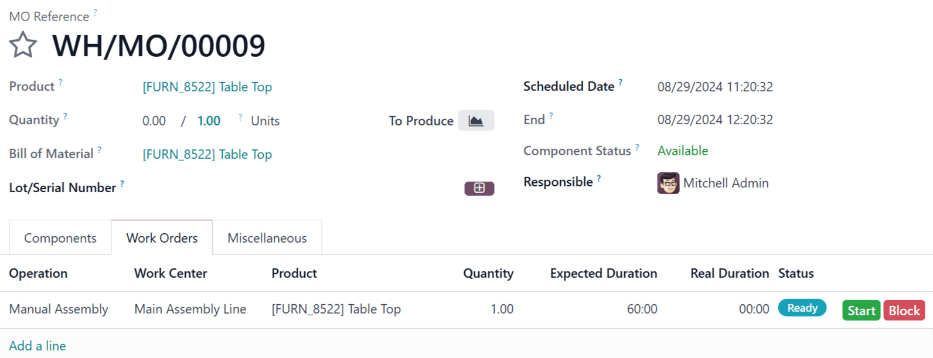

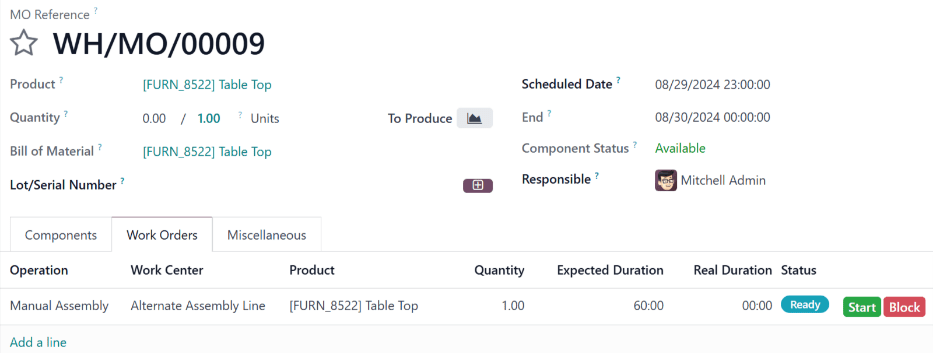

Use case: configure an alternative work center

When a work center is at capacity, it cannot accept any new work orders. Instead of waiting for the work center to become available, it is possible to specify an alternative work center where surplus work orders should be carried out.

Begin by creating a new work center. Configure the Equipment tab so that it has all of the same equipment as the main work center. This will ensure that the same tasks can be carried out at both work centers. Navigate to the main work center and include the new work center in the Alternative Workcenters selection field.

Now, create a new manufacturing order that uses the main work center for one of its operations. The main work center will automatically be selected for the operation in the Work Orders tab. After confirming the manufacturing order, click the Plan button that appears at the top left of the form.

If the main work center is at capacity, the work center selected for the operation will be automatically changed to the alternative work center.

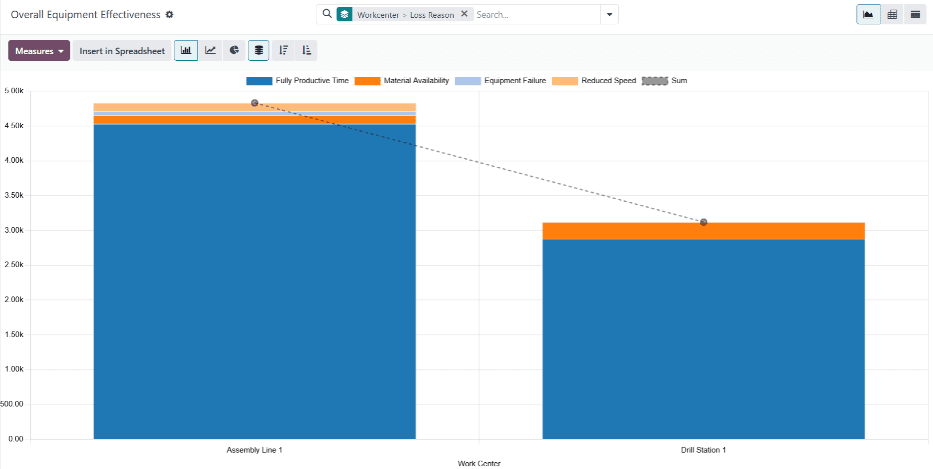

Monitor work center performance

Performance for an individual work center can be viewed by selecting Configuration ‣ Work Centers, and clicking on a work center. A variety of metrics showing work center performance can be viewed at the top right of the form:

- OEE: overall effective efficiency, the percentage of time that the work center has been fully productive

- Lost: the amount of time lost due to work stoppages

- Load: the amount of time it will take to complete the current workload

- Performance: the real duration of work time, shown as a percentage of the expected duration

On this page

Get Help

Contact Support Ask the Odoo Community

- User Docs

- Database management

- Developer

- Contributing

EN

Odoo 18

Work order dependencies

When manufacturing certain products, specific operations may need to be completed before others can begin. In order to ensure operations are carried out in the correct order, Odoo Manufacturing features a work order dependencies setting. Enabling this setting allows for operations on a Bill of Materials (BoM) to be blocked by other operations that should occur first.

Configuration

The work order dependencies setting is not enabled by default. To enable it, begin by navigating to Manufacturing ‣ Configuration ‣ Settings. Then, enable the Work Orders setting, if it is not already active.

After enabling the Work Orders setting, the Work Order Dependencies setting appears below it. Enable Work Order Dependencies, then click Save to confirm the changes.

Add dependencies to BoM

Work order dependencies are configured on a product’s BoM. To do so, navigate to Manufacturing ‣ Products ‣ Bills of Materials, then select a BoM, or create a new one by clicking New.

Learn more

For a complete guide on how to properly configure a new BoM, see the documentation on creating a bill of materials.

On the BoM, click on the Miscellaneous tab, then enable the Operation Dependencies checkbox. This makes a new Blocked By option available in the settings of the Operations tab.

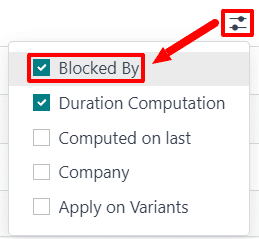

Next, click on the Operations tab. On the top-right of the tab, click on the tab’s settings button, then enable the Blocked By checkbox. This makes a Blocked By field appear for each operation on the Operations tab.

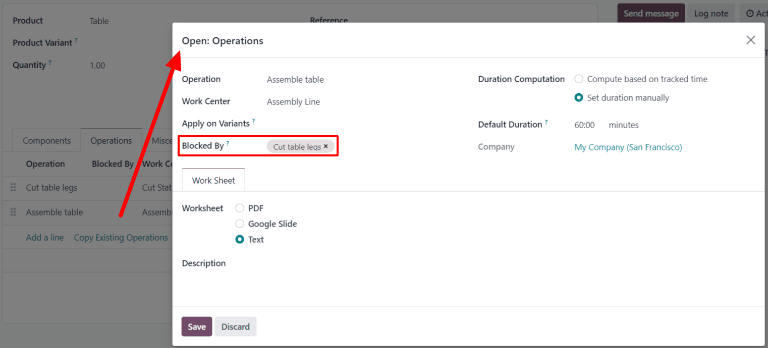

In the line of the operation that should be blocked by another operation, click the Blocked By field, and an Open: Operations pop-up window appears. In the Blocked By drop-down field on the pop-up window, select the blocking operation that must be completed before the operation that is blocked.

Finally, save the BoM by clicking Save.

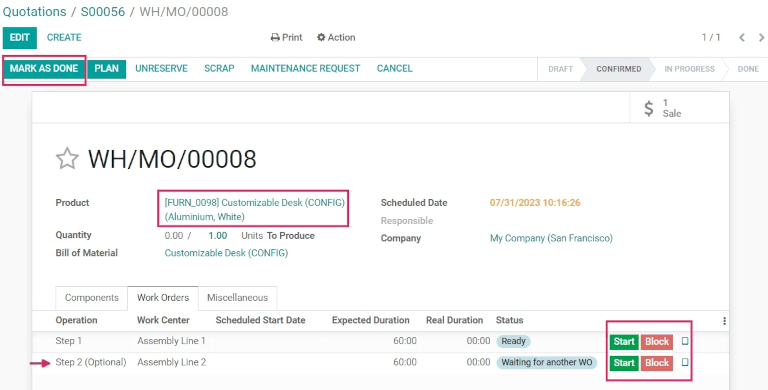

Plan work orders using dependencies

Once work order dependencies have been configured on a BoM, Odoo Manufacturing is able to plan when work orders are scheduled, based on their dependencies. To plan the work orders for a manufacturing order, begin by navigating to Manufacturing ‣ Operations ‣ Manufacturing Orders.

Next, select a manufacturing order for a product with work order dependencies set on its BoM, or create a new manufacturing order by clicking New. If a new manufacturing order is created, select a BoM configured with work order dependencies from the Bill of Material drop-down field, then click Confirm.

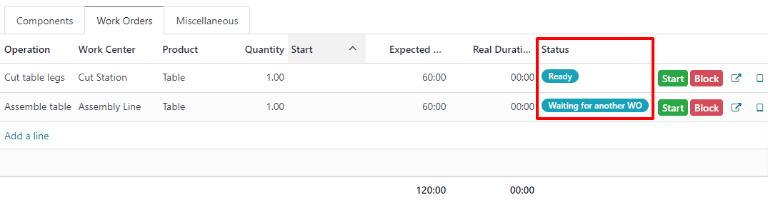

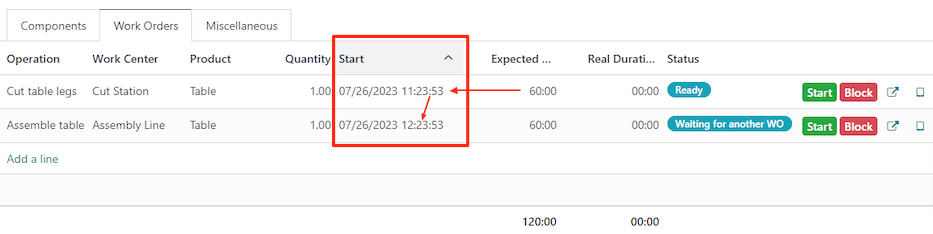

After confirming the manufacturing order, select the Work Orders tab to view the work orders required to complete it. Any work orders that are not blocked by a different work order display a Ready tag in the Status section.

Work orders that are blocked by one or more work orders display a Waiting for another WO tag instead. Once the blocking work order(s) are completed, the tag updates to Ready.

To schedule the manufacturing order’s work orders, click the Plan button at the top of the page. After doing so, the Scheduled Start Date field for each work order on the Work Orders tab auto-fills with the scheduled start date and time. A blocked work order is scheduled at the end of the time period specified in the Expected Duration field of the work order that precedes it.

Example

A manufacturing order is created for Product A. The manufacturing order has two operations: Cut and Assemble. Each operation has an expected duration of 60 minutes, and the Assemble operation is blocked by the Cut operation.

The Plan button for the manufacturing order is clicked at 1:30 pm, and the Cut operation is scheduled to begin immediately. Since the Cut operation has an expected duration of 60 minutes, the Assemble operation is scheduled to begin at 2:30 pm.

Planning by workcenter

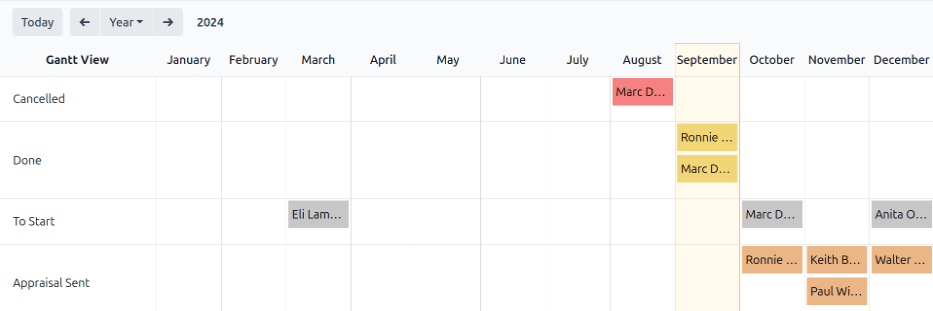

To see a visual representation of how work orders are planned, navigate to the Work Orders Planning page by going to Manufacturing ‣ Planning ‣ Planning by Workcenter. This page shows a timeline of all the work orders scheduled for each operation.

If one work order is blocked by the completion of another, the work order that is blocked is shown as scheduled to start after the work order blocking it. In addition, an arrow connects the two work orders, leading from the blocking operation to the blocked operation.

On this page

Get Help

Contact Support Ask the Odoo Community

- User Docs

- Database management

- Developer

- Contributing

EN

Odoo 18

Master production schedule

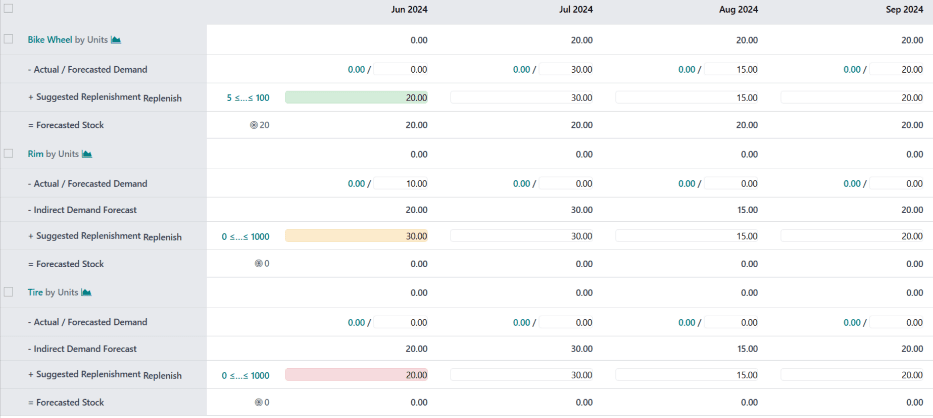

In Odoo’s Manufacturing app, the master production schedule (MPS) is used to manually plan manufacturing orders (MOs) and purchase orders (POs), based on forecasted quantities of products and components.

By considering the impact of confirmed MOs and POs, along with manually adjusted demand forecasts, the MPS can be used to manage long-term product replenishment. This ensures the continued availability of the necessary products and components.

Since the MPS allows for manual intervention, it is useful for replenishing products where the demand of existing sales orders (SOs) does not reflect probable future demand.

Example

A retail store sells artificial Christmas trees during the holiday season. It is currently September, and the store has less than ten Christmas tree MOs confirmed for the month of December.

Despite the number of confirmed MOs, the procurement manager knows that the demand for Christmas trees in December is going to be much higher, once the holiday season starts. As a result, they manually enter a greater demand in the MPS, so they can properly replenish the product in time for the increase in customer demand.

Important

It is essential to remember that the MPS is a MANUAL tool. Adding a product to the MPS does not cause it to be manufactured or purchased automatically. The MPS simply suggests the amount of the product that should be replenished, but requires user input to create the MOs or POs that are used to replenish it.

For this reason, it is recommended that the MPS NOT be used alongside reordering rules for the same product. Because reordering rules are an automated workflow, they conflict with the manual replenishment method of MPS. Using both, in unison, can lead to inaccurate forecasts and the creation of unnecessary replenishment orders.

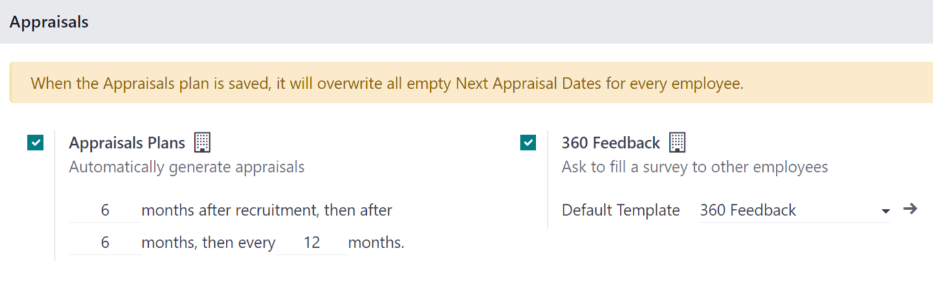

Enable and configure MPS

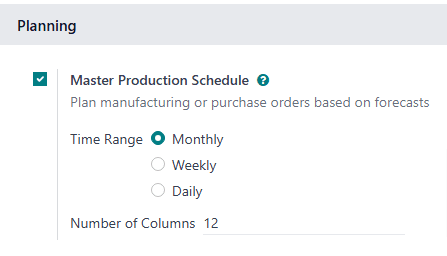

To use the MPS feature, navigate to Manufacturing app ‣ Configuration ‣ Settings, and tick the Master Production Schedule checkbox in the Planning section. Finally, click Save.

After enabling the Master Production Schedule feature, two new fields appear under it on the Settings page: Time Range and Number of Columns.

The Time Range field is used to select the period of time over which planning takes place, and offers three options: Monthly, Weekly, and Daily. For example, if Monthly is selected, the MPS plans the production requirements of products and components on a monthly basis.

The Number of Columns field is used to specify the quantity of the selected Time Range units shown on the MPS page. For example, if the Time Range field is set to Monthly, and 12 is entered in the Number of Columns field, the MPS shows one column for the next 12 months, starting with the current month.

If the values of the Time Range or Number of Columns fields are altered, click Save again to save the changes.

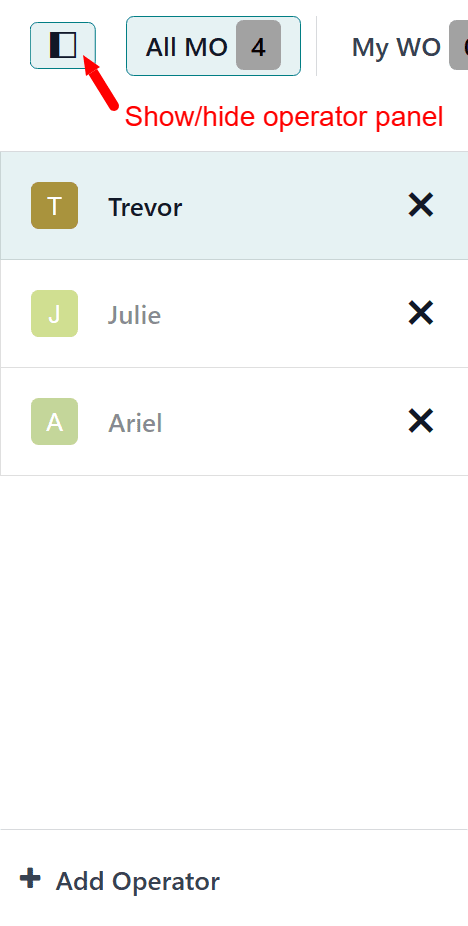

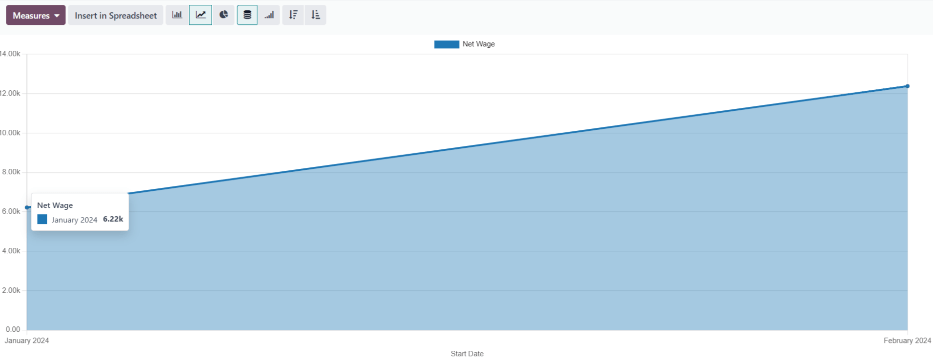

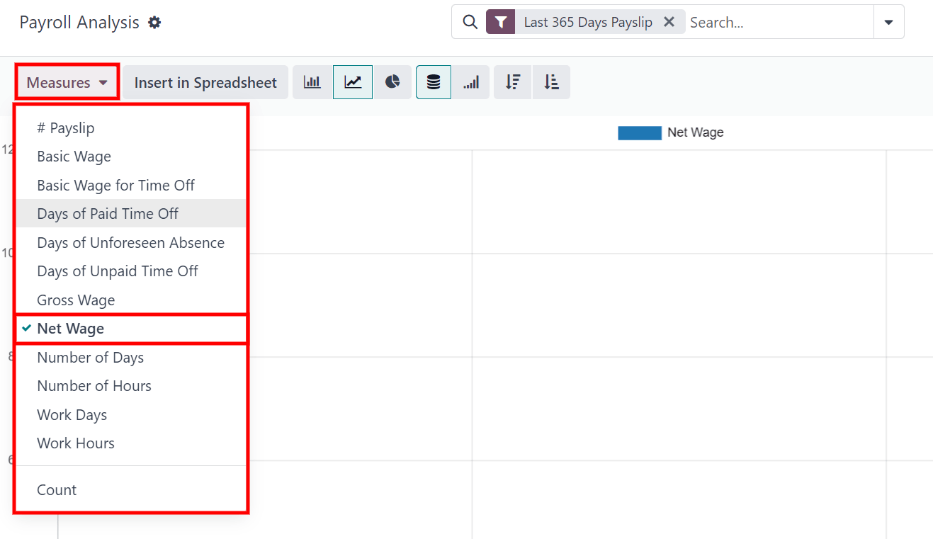

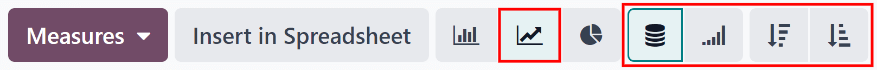

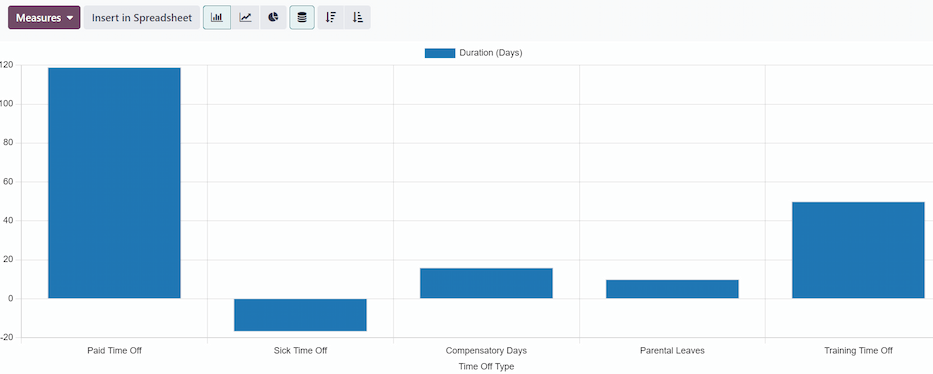

MPS dashboard